All valid.

It's not that I don't like sheds. Welding in 40 deg heat really stinks. And I've spent my fair share of time in heavy wet weather gear. The control over construction is so much better in an enclosed environment.

It was just to point out it is not essential. We could build ships down in the BAE maintenance complex on the dirt if push came to shove.

I've never had the luxury of working in a shed in my entire career. It's a different era.

Just some generic comments.

Undercover construction is where its at. You will get far greater productivity from an undercover yard. Exposing things to rain, snow, massive temperature flucuations, sunlight, bird shit, causes all sorts of problems. Surfaces are never clean, water gets in everywhere, blocks can be different temperatures and therefore different sizes and it can be problematic to get them the same temperature if they are painted differently/ or have different geometries reflecting light differently. Problems and delays. Worker comfort is a real thing, working in modern PPE makes it even harder. But that isn't the only things

We could build in the dirt, but we would be far less efficient, far slower, far more expensive, far less quality. Submarines for example are only built in build halls. Designs are pretty optimized for certain construction methods, as we have found out, going backwards in production techniques can cause problems. Things we built int the dirt would be pretty shit.

Anyone who has had to spend ages to clean up a rusty bit of steel to get a weld know how much more time can be wasted prepping than actual welding.

Thermal expansion will mean on 25m steel (width of a type 26) at a delta of 40C you will have 6.5mm of length difference. Even if you weld it, when they do get to the same temperature you setup internal stresses to ensure failure. Chinese yards where they are scaling up to larger vessels are finding this problem, lots of hull cracking. When dealing with huge blocks of steel in the open, it can take days/weeks for temperatures to balance, and some structures, you will never get it, as one side of the same block will be a different temperature than the other side. This was less of an issue with earlier designs and methods back in the 40's and 50's, but now with blocks or super/grand block construction this just doesn't work, tolerances are tighter, structures more rigid, there is less fat/margin in the design.

Civil construction has this problem all the time, and in many cases, you have to plan construction around the seasons or plan long delays into the construction process or apply many costly small measures to assist. In the northern hemisphere, there are times of the year they can't pour concrete, and basically some parts of construction cannot occur, same in tropical areas in wet seasons. Sometimes the design has to be changed to give extra strength to mitigate weakness due to weather in construction, you pay for it in the end.

The facilities are also better for productivity, so much more support is built in, access, toilets, fire fighting, first aid, welding gear, power, tools etc. You can rebuild a car engine in the dirt, but its a hell of a lot better in a workshop with a hoist. Monitoring productivity is also easier. We are talking gains not of a few % but of hundreds of %. Frame and truss plants make housing frames

30-40 times the productivity of a team of carpenters on site. Two workers can build the housing frames for 20 houses in a day, and those workers would be happier and the quality arguably better.

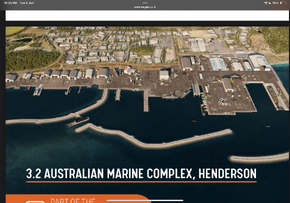

One of the things I think we did get right is building huge build halls with detached buildings for all the other functions. The CIVMEC & Osborne facility was overbuilt in a good way. Arguably the greatest limitations aren't CIVMEC facility, but the contracting and specialized workforce around it.

With drones now everywhere, everyone is rethinking outside building. A fly over of a drone over these sites happens all the time. Which is a security risk of course, but also they could very effectively disrupt the build process. How many shipyard fires have we seen in the past few years that have cause devastation to ships and facilities. Australia is one of the few places where we have these covered modern well built structures, and pretty tight control of the airspace around them.