So HMAS Supply is ~175 metres long, HMAS Canberra is 55 meters longer at 230 metres.

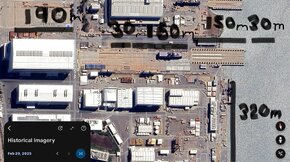

According to the Syncrolift website, the lift at Henderson is limited to 150m x 25m x 9.4m with a mass limit of 8,000t. The longest Dry Berth is restricted to 190m length and a width of 24.5m.

Remembering also that ANZAC Class refit work is currently (at least as per Google Maps) carried out in the open air rather then in a covered dock or build hall which is probably not ideal with regards to weather and using mobile cranes rather then overhead gantry cranes.

So at currently Henderson cannot refit a Supply class tanker let alone build one. And the LHD's are significantly bigger again.

The Syncrolift at Osborne *might* be able to lift a Supply class, but would not be able to deal with Canberra.

BAE Henderson

syncrolift.com

ANI’s Operations team is responsible for the operation and maintenance of common use infrastructure at the Osborne Naval Shipyard. CUI provides critical shipyard infrastructure to support and service naval shipbuilding programs and commercial users.

www.ani.com.au