Really looks like they should consider an ESSM-ER, by adding a booster to it.

Royal Australian Navy Discussions and Updates 2.0

- Thread starter OPSSG

- Start date

The legal framework being referred too does it include imported materials used by Russia

www.armscontrol.org

.)

www.armscontrol.org

.)

Russia Uses North Korean Missiles Against Ukraine | Arms Control Association

I can't help but notice that all our local production is focused on strike missiles. If however we run out of the defence missiles, particularly ESSM, then we can't put any ships to sea. I don't know what our inventory is, but I suspect it's not more than a couple of refills, say 500 above that at sea (I could be wrong and maybe we have a massive warehouse full of them). If Ukraine has taught us anything, wars aren't won in three days, and instead quickly become one of attrition. I would view that without our own ESSM manufacturing capability, we might find ourselves exhausted within a few weeks, and then our ships are stuck in port.

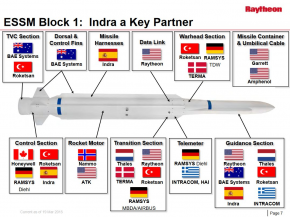

Sounds like we should talk more to Honeywell, RAMSYS, Thales, BAE, Raytheon, Nammo, Indra. etc to set up local shop or expand it.

Who are exactly who we should be talking to about any missile or munition production. The koreans and Turks and others have entire local missiles, we could probably build, again, some of these are also looking for second production sources out of country.

Modern manufacturing and technologies have really changed things. Labor costs are less of an issue due to ever increasing automation. Where as previously a whole bunch of skilled technical machinists would be required to manufacture everything on it, a lot of components can just be printed on commercial 3D printers in PEEK/PEKK or Ultem. Or be sintered manufacturers on direct to metal printers out of stainless, titanium, tungsten, aluminium etc. 10 years ago, such parts would have required a lot of machining to get them good enough, meaning it wasn't really viable. 20 years ago when many of these projects were established they didn't exist as technologies to use at all.

Now you could buy 100 machines have have them churning out product 24-7-365. One machinist can run 10-50 machines. A line can change via software in one minute to a different product. Productivity has exploded, potentially, if you take advantage of it.

Guidance used to be black magic back in the 1970's. Now its trivial to throw together some OTS civilian gear and make a drone that can reliably hit 1m accuracy over a thousand km for less than $1000. Vision systems are mind blowingly better than they were even in the early 2010's.

Now is the time to launch projects in this space...

To be fair, your idea was rather more barely guided flak rocket than cheap 'n' cheerful SAM.I did suggest something very similar a long time ago, but in the context of more point defence local produced VLS silo filler... anyway it was universally dismissed as a dumb idea, and we are in a period of production re-arming & maybe recently announced local domestic missile manufacture might mitigate this somewhat anyway??

That said, there certainly looks like there's some space for cheaper SAMs to mass produce if the shooting keeps up... The Tamir SAM used in Iron Dome might be a reasonable outline (if we trust the dubious source of wikipedia it's about ~US$100,000 per missile vs ~US$1.5M for an ESSM) for the point/local area defence role. Not sure if there's any existing equivalent out there for the medium and long range area defence roles.

Well...Now is the time to launch projects in this space...

Titomic has developed tech that'd effectively allow the airframe to be easily 3D printed.

Gilmour Space has developed 3D printable rocket fuel.

Looks like guidance is the only serious hole that'd need filling...

Last edited:

Guidance seems to be an evolving challenge with reports from Ukraine that Himars accuracy has been effected by electronic warfare ,the U.S may eventually address this and as the A.D.F has purchased these sooner rather than later ,Russia could be expected to export such technology further east

www.businessinsider.com

.

www.businessinsider.com

.

US-supplied HIMARS 'completely ineffective' against superior Russian jamming technology, report says

Russian jamming can cause the HIMAR missiles to miss targets by 50ft or more, The Washington Post reported.

The problem is in ukraine, they are firing most weapons designed/made in pre 2010. In a different era. Imagine using 1920's weapons in late WW2 1945.. The countermeasures are now orders of magnitude better, processing is multiple orders of magnitude better. It doesn't mean that tech doesn't have a place, but being outmatched makes it very hard.

In 1991 GPS spoofing, IR blinding, radar spoofing was all really cutting edge stuff, the domain of basically the US on the battle field. Now basically a flipper, a childs toy with a tricked and amped up transmitter can do those things. The 80486DX in a 1995 JDAM isn't advanced, its positively ancient. A watch literally has a million times more processing power/memory. So anything 1990's or early 2000's based (which is based off commercial 80 or 90s tech), relying on reliable GPS to give guidance, doing a flight path that has like 1 or 2 way points, isn't ideal at this point. early 90's accelerometers are crap, verse, what would exist in a mid 2000's wii remote, which has like 6 of them, an IR camera, onboard processing, wireless communication on a childrens toy from the early 2000's that was a $25 retail item has better sensors in some regards than a large $100,000 weapon from 1989..

Which is why IMO there has been a return to some pretty basic, pre 1990's level tech. Ultimately mass matters. Physics still counts, no matter what technology it is facing. That and pre 1990's stuff was made in much larger volumes to fight longer wars, and be less technology demonstrators but wars of industrial capability. What is happening old tech, is getting some kits to make it more useful.

There are of course high tech weapons, but they are precision tools, cherrished by both sides, as limited stock, to take out high value efforts, used in conjunction with mass fires from simpler more plentiful weapons. Drones can be used, while a hail of 152mm rounds fall from the sky. Cruise missiles are used at the same times as unguided rocket artillery. Drones drop adapted grenades or mines. The hand grenade you used to throw 10m, can now strike people 3-5km away.

In 1991 GPS spoofing, IR blinding, radar spoofing was all really cutting edge stuff, the domain of basically the US on the battle field. Now basically a flipper, a childs toy with a tricked and amped up transmitter can do those things. The 80486DX in a 1995 JDAM isn't advanced, its positively ancient. A watch literally has a million times more processing power/memory. So anything 1990's or early 2000's based (which is based off commercial 80 or 90s tech), relying on reliable GPS to give guidance, doing a flight path that has like 1 or 2 way points, isn't ideal at this point. early 90's accelerometers are crap, verse, what would exist in a mid 2000's wii remote, which has like 6 of them, an IR camera, onboard processing, wireless communication on a childrens toy from the early 2000's that was a $25 retail item has better sensors in some regards than a large $100,000 weapon from 1989..

Which is why IMO there has been a return to some pretty basic, pre 1990's level tech. Ultimately mass matters. Physics still counts, no matter what technology it is facing. That and pre 1990's stuff was made in much larger volumes to fight longer wars, and be less technology demonstrators but wars of industrial capability. What is happening old tech, is getting some kits to make it more useful.

There are of course high tech weapons, but they are precision tools, cherrished by both sides, as limited stock, to take out high value efforts, used in conjunction with mass fires from simpler more plentiful weapons. Drones can be used, while a hail of 152mm rounds fall from the sky. Cruise missiles are used at the same times as unguided rocket artillery. Drones drop adapted grenades or mines. The hand grenade you used to throw 10m, can now strike people 3-5km away.

Todjaeger

Potstirrer

Ahem. The M1919 Browning MG came to my mind immediately, as did the slightly earlier M1917 Browning MG. For certain things, a piece of kit that is an old design can still be perfectly adequate and/or relevant, it largely depends upon the situation.The problem is in ukraine, they are firing most weapons designed/made in pre 2010. In a different era. Imagine using 1920's weapons in late WW2 1945.. The countermeasures are now orders of magnitude better, processing is multiple orders of magnitude better. It doesn't mean that tech doesn't have a place, but being outmatched makes it very hard.

What might make sense would be for Australia to license and/or contract for local production of some air defence missile or missiles, that are in Australian service. TBH I rather doubt that Australia has both the technical expertise and interest (yes, both are required) for there to be a domestic Australian air defence missile. I suspect that the cost to design one which would 'adequate' to be operated alongside or in place of an existing ADF air defence missile would either too expensive to develop for Australia, or it would require too much technical resources to get into service and then keep up to date.

From the Australian Financial review.

www.afr.com

www.afr.com

-5 builders have 3 weeks to outline pitch for RANs new GPF, including how soon and how much.

Questions surface over fast-tracked $10b warships

Shipbuilders have been given just three weeks to outline their opening pitch to build new frigates for the navy.

-5 builders have 3 weeks to outline pitch for RANs new GPF, including how soon and how much.

iambuzzard

Well-Known Member

Unfortunately it's behind a paywall.From the Australian Financial review.

Questions surface over fast-tracked $10b warships

Shipbuilders have been given just three weeks to outline their opening pitch to build new frigates for the navy.www.afr.com

-5 builders have 3 weeks to outline pitch for RANs new GPF, including how soon and how much.

Sorry about that but it wasn’t before.Unfortunately it's behind a paywall.

-“approach to market” requesting information for the general purpose frigate was sent to five foreign shipbuilders on Friday, asking them to provide details of how soon they could build the new warships, where they would build them and what they would cost. Shipbuilders have been given three weeks to outline their opening pitch.

-Five shipbuilders, Mitsubishi Heavy Industries (Japan), Navantia (Spain), TKMS (Germany) and Koreans Hanwha Ocean and Hyundai. Government has vowed to choose the winning design next year, start construction in 2026, receive the first boat by 2029 and have it in service in 2030.

-Separate request covering how the companies plan to transfer technology to Australia and grow a supply chain to build the remaining ships in Perth will be released later.

-The need for a speedy acquisition, the government has ruled out making wholesale changes to the design. This means the cutting-edge CEA radars are not expected to be used on the new frigates. The bidders have been told to offer baseline versions of warships that are most closely in service with other countries, with the only changes that will be entertained are those required because of obsolete equipment.

Last edited:

iambuzzard

Well-Known Member

Thanks ReptiliaSorry about that but it wasn’t before.

-“approach to market” requesting information for the general purpose frigate was sent to five foreign shipbuilders on Friday, asking them to provide details of how soon they could build the new warships, where they would build them and what they would cost. Shipbuilders have been given three weeks to outline their opening pitch.

-Five shipbuilders, Mitsubishi Heavy Industries (Japan), Navantia (Spain), TKMS (Germany) and Koreans Hanwha Ocean and Hyundai. Government has vowed to choose the winning design next year, start construction in 2026, receive the first boat by 2029 and have it in service in 2030.

-Separate request covering how the companies plan to transfer technology to Australia and grow a supply chain to build the remaining ships in Perth will be released later.

-The need for a speedy acquisition, the government has ruled out making wholesale changes to the design. This means the cutting-edge CEA radars are not expected to be used on the new frigates. The bidders have been told to offer baseline versions of warships that are most closely in service with other countries, with the only changes that will be entertained are those required because of obsolete equipment.

Todjaeger

Potstirrer

These things, plus the very significant time crunch involved, leads me to think that this whole thing will end up falling over. Basically this is very much looking to me like a programme that gov't is putting together to fail. I suspect one (or more) of the following will happen.Sorry about that but it wasn’t before.

-“approach to market” requesting information for the general purpose frigate was sent to five foreign shipbuilders on Friday, asking them to provide details of how soon they could build the new warships, where they would build them and what they would cost. Shipbuilders have been given three weeks to outline their opening pitch.

-Five shipbuilders, Mitsubishi Heavy Industries (Japan), Navantia (Spain), TKMS (Germany) and Koreans Hanwha Ocean and Hyundai. Government has vowed to choose the winning design next year, start construction in 2026, receive the first boat by 2029 and have it in service in 2030.

-Separate request covering how the companies plan to transfer technology to Australia and grow a supply chain to build the remaining ships in Perth will be released later.

-The need for a speedy acquisition, the government has ruled out making wholesale changes to the design. This means the cutting-edge CEA radars are not expected to be used on the new frigates. The bidders have been told to offer baseline versions of warships that are most closely in service with other countries, with the only changes that will be entertained are those required because of obsolete equipment.

- The original/overseas builder will be unable to get the first batch of vessels completed in the planned times.

- The intended Australian builder & yard will be unable to get their builds started and/or completed in their planned times.

- The vessels once built will not be able to enter RAN service in a timely fashion because of systems not currently supported by the RAN.

- The completed vessels will not be able to be taken into RAN service until regulatory compliance issues are resolved with the vessels.

- The selected design itself, and/or its fitout, will prove to be inadequate for the RAN's service needs

Aside from this looking like even more of a cluster, I am reminded of the saying that, "haste makes waste."

These things, plus the very significant time crunch involved, leads me to think that this whole thing will end up falling over. Basically this is very much looking to me like a programme that gov't is putting together to fail. I suspect one (or more) of the following will happen.

Keep in mind we are talking about a build programme which is to select one of the four (or five) possible designs on offer from either Germany, Japan, Spain or S. Korea. AFAIK none of these designs utilize many of the systems and interfaces used by the RAN, and it is even distinctly possible that standard shipbuilding codes (size of ladders, piping, wiring, fire suppression systems, etc.) might not be compliant with Australian standards. Further, if Austal is going to be the entity in Australia which builds ~eight of the frigates, does Austal currently have (or have access to) the facilities and infrastructure which would be required to build the chosen class of vessels? Does Austal have the workforce in place, with the proper training and skills, to actually build modern warships? Or would Austal need to build or expand facilities to have a yard for the build, and/or raise and train a workforce to run whatever build yard Austal uses in WA?

- The original/overseas builder will be unable to get the first batch of vessels completed in the planned times.

- The intended Australian builder & yard will be unable to get their builds started and/or completed in their planned times.

- The vessels once built will not be able to enter RAN service in a timely fashion because of systems not currently supported by the RAN.

- The completed vessels will not be able to be taken into RAN service until regulatory compliance issues are resolved with the vessels.

- The selected design itself, and/or its fitout, will prove to be inadequate for the RAN's service needs

Aside from this looking like even more of a cluster, I am reminded of the saying that, "haste makes waste."

Civmec may be involved? The government continually say ‘built at the Henderson precinct’.

Civmec and the GPF designer working together post Arafura and Austal with the fit out? Similar to the Tasman proposal I’m guessing.

Another 150m Hall near Austal or where Silveryachts is located would take a very long time to get up and running with a new workforce.

So we are just going to look at baseline designs that require minimum changes.Sorry about that but it wasn’t before.

-“approach to market” requesting information for the general purpose frigate was sent to five foreign shipbuilders on Friday, asking them to provide details of how soon they could build the new warships, where they would build them and what they would cost. Shipbuilders have been given three weeks to outline their opening pitch.

-Five shipbuilders, Mitsubishi Heavy Industries (Japan), Navantia (Spain), TKMS (Germany) and Koreans Hanwha Ocean and Hyundai. Government has vowed to choose the winning design next year, start construction in 2026, receive the first boat by 2029 and have it in service in 2030.

-Separate request covering how the companies plan to transfer technology to Australia and grow a supply chain to build the remaining ships in Perth will be released later.

-The need for a speedy acquisition, the government has ruled out making wholesale changes to the design. This means the cutting-edge CEA radars are not expected to be used on the new frigates. The bidders have been told to offer baseline versions of warships that are most closely in service with other countries, with the only changes that will be entertained are those required because of obsolete equipment.

Surely you would have to eliminate the ALFA3000 straight away as it doesn't actually exist. Neither does the Daegu class FFX Batch III. So we are down to three contenders. In fact you could probably knock out the remaining Asian contenders because they have entirely different combat systems and other gear used by the Australian navy.

So there you go, MEKO A-200 wins by default.

Actually scratch that. Just get the Type 31 and build it in Poland.

Last edited:

Todjaeger

Potstirrer

As I understand it, Civmec already has enough work to stay busy meeting the needs for oil & gas exploration vessels and following how the Arafura-class OPV build has been going, is going to focus on commercial and not pursue defence work. If the Civmec facilities and workforce are occupied building exploration or support vessels and platforms, then they would not really be available to build parts of the XYZ-class frigates and either way, neither Civmec or Austal (in Australia) has experience installing and integrating complex weapon, sensor and combat management systems in naval vessels.Civmec may be involved? The government continually say ‘built at the Henderson precinct’.

Civmec and the GPF designer working together post Arafura and Austal with the fit out? Similar to the Tasman proposal I’m guessing.

Another 150m Hall near Austal or where Silveryachts is located would take a very long time to get up and running with a new workforce.

So we are just going to look at baseline designs that require minimum changes.

Surely you would have to eliminate the ALFA3000 straight away as it doesn't actually exist. Neither does the Daegu class FFX Batch III. So we are down to three contenders. In fact you could probably knock out the remaining Asian contenders because they have entirely different combat systems and other gear used by the Australian navy.

So there you go, MEKO A-200 wins by default.

Actually scratch that. Just get the Type 31 and build it in Poland.

The Alpha 3000 is the Saudi Al Jubail class corvette with a 5m hull extension and Aus equipment, seems risky but likely cheapest option.

The FFX batch III is the Chungnam class, 1 exists currently, 5 more by mid 2028. Daegu FFX II, not a chance. FFX batch IV also from late 2028.

If the Brits stopped at 5 Type 31s and with no follow on frigate, they could continue to build more for Aus but the timeline would move to early 2030s delivery. Not on the list, not a chance.

Mogami is too small internally, improved FFM won’t exist for another 2 years.

MEKO A200 probably the front runner, MEKO A210 too risky, doesn’t exist, none planned. NZ probably also keen on the A200.

Last edited:

Civmec owns the Foragacs yard in Newcastle, they will claim to history they can build anything. However, CIVMEC seems very focused on Henderson. The Civmec Foragacs yard might have some work picking up with the Raymond terrace bypass coming up. There is still quite the infrastructure build going on in Perth and elsewhere. The Arfuras are 9LV, Saab Australia usually do most of the tricky stuff anyway. CIVMEC could away fly people in from Perth, and acquire local talent by raiding Thales who has most the maintenance contracts on frigates and destroyers at Co dock. But do they want to do that? Not really. I think CIVMEC is very cautious about taking on future defence work, its too erratic, too high risk for them to bid.Civmec or Austal (in Australia) has experience installing and integrating complex weapon, sensor and combat management systems in naval vessels.

What you need is a large local entity or local division of an international to run it. Japan has a larger footprint in Australia. Mitsubishi could fly over 100 workers, house, office, pay them, until locals can be trained or recruited. I think Korea is hungrier to strike a deal.

I'm not sure Germany or Korea or Spain could do that at this stage. Maybe. They have 3 weeks to put together a plan..

The idea that this project is contingent on the actual design is absurd. Its the project that will be assessed, not the design as an isolated artifact. How much industrial capacity can be thrown at the project as fast as possible.

We aren't selecting a design, and building it all by our selves in isolation. We are selecting a project, that someone else will likely build whole ships externally, and then try to frantically kick start local production and lead and manage it, not just of the ship but of the whole eco system to build and support it. Someone who can swallow the risks of the projects, who isn't driven by profit, who understands the context and the imperative.

By that standard, the Koreans and the Japanese have a lot of skin in the game. If they fail, they face existential risk. If this an other projects go south, failure to deter China will result in very, very bad outcomes, likely loosing thousands, perhaps millions of citizens in conflict. The Spanish, while not facing the same risk, are totally economically desperate and politically motivated. Failure to secure multiple large international contracts over the next 5 years may help fuel and see the breakup of Spain and collapse of state funded enterprises. Spain which has an unemployment rate still over ~12%.. They have been making noise.

3 weeks guys. Please feel free to discuss the options, but realize picking a winner via crystal ball is a fools errand. Until the 3 weeks is up, we and they themselves don't even know if the contenders will even submit a proposal or what that might look like.

iambuzzard

Well-Known Member

I don't think a 57mm main gun is going to cut the mustard with the RAN. For commonality it needs to be a 127mm.So we are just going to look at baseline designs that require minimum changes.

Surely you would have to eliminate the ALFA3000 straight away as it doesn't actually exist. Neither does the Daegu class FFX Batch III. So we are down to three contenders. In fact you could probably knock out the remaining Asian contenders because they have entirely different combat systems and other gear used by the Australian navy.

So there you go, MEKO A-200 wins by default.

Actually scratch that. Just get the Type 31 and build it in Poland.

Todjaeger

Potstirrer

TBH I am not particularly concerned about which design is selected, because from my POV other aspects of the programme make it rather high risk, no matter which design is ultimately selected or who the overseas builder ends up being.Civmec owns the Foragacs yard in Newcastle, they will claim to history they can build anything. However, CIVMEC seems very focused on Henderson. The Civmec Foragacs yard might have some work picking up with the Raymond terrace bypass coming up. There is still quite the infrastructure build going on in Perth and elsewhere. The Arfuras are 9LV, Saab Australia usually do most of the tricky stuff anyway. CIVMEC could away fly people in from Perth, and acquire local talent by raiding Thales who has most the maintenance contracts on frigates and destroyers at Co dock. But do they want to do that? Not really. I think CIVMEC is very cautious about taking on future defence work, its too erratic, too high risk for them to bid.

What you need is a large local entity or local division of an international to run it. Japan has a larger footprint in Australia. Mitsubishi could fly over 100 workers, house, office, pay them, until locals can be trained or recruited. I think Korea is hungrier to strike a deal.

I'm not sure Germany or Korea or Spain could do that at this stage. Maybe. They have 3 weeks to put together a plan..

The idea that this project is contingent on the actual design is absurd. Its the project that will be assessed, not the design as an isolated artifact. How much industrial capacity can be thrown at the project as fast as possible.

We aren't selecting a design, and building it all by our selves in isolation. We are selecting a project, that someone else will likely build whole ships externally, and then try to frantically kick start local production and lead and manage it, not just of the ship but of the whole eco system to build and support it. Someone who can swallow the risks of the projects, who isn't driven by profit, who understands the context and the imperative.

By that standard, the Koreans and the Japanese have a lot of skin in the game. If they fail, they face existential risk. If this an other projects go south, failure to deter China will result in very, very bad outcomes, likely loosing thousands, perhaps millions of citizens in conflict. The Spanish, while not facing the same risk, are totally economically desperate and politically motivated. Failure to secure multiple large international contracts over the next 5 years may help fuel and see the breakup of Spain and collapse of state funded enterprises. Spain which has an unemployment rate still over ~12%.. They have been making noise.

3 weeks guys. Please feel free to discuss the options, but realize picking a winner via crystal ball is a fools errand. Until the 3 weeks is up, we and they themselves don't even know if the contenders will even submit a proposal or what that might look like.

I am also not concerned about whether the selected design is suitable or appropriate for the source nation as built/spec'd but whether it is appropriate for Australia. For instance, suppose the S. Korean Chungnam-class (FFX III) FFG were selected, with the lead vessels to be built in S. Korea and at least the lead vessels built as designed/fitted for S. Korea, this would mean that Australia would then need to bring into service kit used by S. Korea but not otherwise in Australian service. This in turn would mean that operators and maintainers would need to be trained and skilled to use and support the new-to-Australia kit. Australia would also need to establish the parts and logistics supply chain to keep the new kit in service. This would also apply to potentially all new systems that Australia might have to bring into service, this could even apply to minor things which are different like possibly electrical, cable or networking connections. Imagine a new GPF introduced to RAN service, that suddenly develops an electrical problem because of something like a fuse failing, which then needs a resupply.

There is also the question of build slot access and availability. I suspect that a design which adheres closely to what the source company's yard is producing could be available from a hot production line within the time permitted. However, with less Australian content or design input, then the more work the RAN has to do in order to get the new class into service.

Stern ramp with dedicated minehunting usv on the Mitsubishi designs stand out but both are over 5,000tons, 133m + 142m.

New Cairns and Darwin shiplifts(around 120m, 5,000 ton capacity), current infrastructure at Henderson + land space, cost and familiarity with designer/product, GPF range, proven design built in numbers and on schedule, currently in service with multiple nations makes the 121m, 3,700 ton A200 the clear favourite. If the Anzac mast can be fitted, even better. 16 VLS, possibly 24 forward, (mixed tactical/strike) or total with adaptable deck launcher, 2-3 quad nsm launchers, 127mm MG, secondary gun or DEW, towed array, 120 crew.

New Cairns and Darwin shiplifts(around 120m, 5,000 ton capacity), current infrastructure at Henderson + land space, cost and familiarity with designer/product, GPF range, proven design built in numbers and on schedule, currently in service with multiple nations makes the 121m, 3,700 ton A200 the clear favourite. If the Anzac mast can be fitted, even better. 16 VLS, possibly 24 forward, (mixed tactical/strike) or total with adaptable deck launcher, 2-3 quad nsm launchers, 127mm MG, secondary gun or DEW, towed array, 120 crew.

Last edited: