Both Marles and Conroy said, design chosen in 2025, cut steel in 2026, the first in service by the end of the decade and all 3 frigates built overseas in service before the first Hunter in 2034.Not a lot of other options.

I do think that actually beating the Hunter into service is being optimistic even with an overseas build. It will take at least a year for selection maybe another year for contacts and then of course the design phase begins. They will probably be lucky if they can start cutting steel before the end of the decade.

With the ANZACs probably all out of service by the mid 2030s we could have a smallish surface fleet of 3 DDGs perhaps a couple of Hunters and maybe three OS built GP frigates. Not ideal.

Royal Australian Navy Discussions and Updates 2.0

- Thread starter OPSSG

- Start date

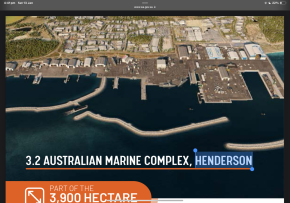

A recent post mentioned that there were four - yes 4 - Anzac frigates on hard stands at Henderson at the present time.What else is high and dry in the left of the picture?

HMAS Anzac will be scrapped immediately. The others are either in for upgrades or awaiting crew AFAIR

MB

Todjaeger

Potstirrer

Such a timeframe might be possible, if everything were to occur just as needed. OTOH such a timeframe is IMO quite ambitious (at best, overly ambitious is also quite possible) which could easily encounter lags or delays at multiple stages.Both Marles and Conroy said, design chosen in 2025, cut steel in 2026, the first in service by the end of the decade and all 3 frigates built overseas in service before the first Hunter in 2034.

One thing I am quite curious about is why there has been a two year delay in the entry of the lead Hunter-class frigate into service. If memory serves the plans had been for the lead ship to be completed c.2029 before commencing trials expected to run through 2031/2032 with then entry into service in 2032. If the entry is now expected to come in 2034 instead, is that because trials are expected to take another two year? Or is it because construction of the lead ship is now expected to take until 2031-ish? If either of these are the case, then I would have to ask, "why?" In a similar vein, the prior plan IIRC would have had the 2nd vessel laid down in the ASC facility alongside the lead ship before the lead ship is completed and that for most of the frigate build there were to be two vessels in different stages of construction at any given point in time. At this stage I have to wonder if work is being deliberately slowed, rather than have work accelerated to bring the Hunter-class into RAN service earlier.

With respect to a 'new' frigate design to built for RAN service, with the first three vessels constructed overseas... I will rather pessimistically state, "we shall see," since such a compressed timeframe (~ten years from design selection to lead vessel's entry into service) has multiple points where this could easily fail. Even if the timeline were able to be maintained, it is quite possible that the new vessels or even possibly the design itself is fraught with issues and overall rather unsuitable for RAN service. Even worse, with a year to select the design and then another year before first steel is to be cut, this means that what could potentially render a design unsuitable could be something 'built-in' in a way that cannot be viably made right.

Also, all of this is even before one considers how long such vessels would likely serve in the RAN, and how long their fitouts would be reasonably viable. If one looks now, yes a 16-cell VLS is an improvement over the 8-cell VLS fitted aboard the RAN ANZAC-class frigates but remains half what the USN is planning for their lower tier warships. Yes, minimally/optionally-crewed largely autonomous vessels might be able to operate close to/alongside RAN vessels and essentially serve as floating magazines and launching platforms, if (big IF) the designs can be made to work as intended. Right now it is quite possible that that such intentions could prove to be a bit more sci-fi than actually deliverable capability.

I also have questions about plans to presumably have the Australian Marine Complex in WA begin building frigates with among the questions being who (which company) will being doing so, since there are several with facilities at the site. Relating to that, which companies actually have both the facilities and experience & skilled workforce to do such work in WA? One area of concern is that whatever shipbuilding concern ends up getting selected to build in WA might find itself either needing to recruit and then skill a workforce or find itself poaching (or at least attempting to) skilled workers from ASC/BAE in Osborne in SA and likely to the detriment of either the surface or sub build programmes taking place there.

All in all, I do not really have a good feeling about what has come out but that is little surprise TBH.

To put things in perspect, the Arafura, a relatively simple design and under 2000 tons, was selected in late 2017, construction commenced in mid 2019, and it is scheduled to enter service later this year. The new GP frigates will be far more complex then that. A local build might not commence until well after the overseas build. I think a 10 year delivery time for the first frigate would be doing pretty well for a local build.Both Marles and Conroy said, design chosen in 2025, cut steel in 2026, the first in service by the end of the decade and all 3 frigates built overseas in service before the first Hunter in 2034.

Off a hot overseas production line it may be possible to churn these out fairly quickly. In fact the government is actually reliant on it. I actually think an inservice date of around the mid 30s for the overseas builds is quite possible.

Assuming a 30 year life for the ANZACs that would give us 3 Hobarts ,1 or 2 Hunters, 3 to 5 new frigates. So a surface combat fleet between 7 to 10 ships when the last ANZAC leaves service in 2036. I suspect the slippage in delivery times for the Hunter will be to partly free up funds for the new GP frigate, BAE say they can increase the production rate for extra money.

Obviously a quick build of the first three GP frigates is vital.

One thing that doesn't seem to get much mention is how China is systematically destroying shipbuilding around the world. A lot of shipbuilders are struggling for orders as China are dominating the shipbuilding market. European, South Korean and Japanese shipbuilders have been hit hard. Probably good for Australia if you are looking for cheap, fast overseas manufacturing but bad for the west overall as China now has a massive shipbuilding capacity.

The thing is, the more you do up front the greater the efficiencies, in schedule and cost, down the track.A quick googles see that with the exception of the Tasman corvette (which is not actually shortlisted), all of the others would require massive integration, test, verification and validation efforts at great cost before any of the SM2/SM6/ASROC or NSM munitions above could be even placed in their VLS cells let alone launched using all of those bespoke sensor suites. It looks like the mother of all non recurring engineering costs. This is looking like the dumbest of dumbest ideas ever dreamed up with no hope of ever 'seemlessly networking' in the ADF's single fused digital battlespace C4I systems without decades of software issues/trials/certification ect ect ect. A money pit that will burn up ridiculous amounts of cash that could be spent elsewhere.

The trick is getting the right balance.

The Hunters, with their extensive design and development on a new design reference design, could be our Arleigh Burke in a way the F-100/Hobart never could. They are potentially the start of a family like the USN Spruance, a core design that gave the USN an ASW specialist destroyer, a DDG, an AEGIS CG, updated ASW Spruances fitted with a Mk-41, became land attack strike platforms. There were even helicopter and STO/VL designs.

The tier 2 will be our equivalent to the Perry Class FFGs, the question is, how much do we invest in integrating their systems design with ADF spec equipment, versus, integrating their legacy systems with in the ADF support structures.

It has to be one or the other, neither is cheap or easy.

Todjaeger

Potstirrer

The above is an area of concern for me re: the proposed 11 ship Tier 2 build. If design selection is to be done by 2025 with first steel cut in 2026 with a goal of lead ship built overseas being in RAN service by/before 2034, this does not provide much time for upfront work to be done which would be conducive to the RAN and ADF-used systems.The thing is, the more you do up front the greater the efficiencies, in schedule and cost, down the track.

The trick is getting the right balance.

Heck, the proposed timeframes do not even provide much opportunity for detailed design work to be done once the design has been selected and before first steel is to be cut. This in turn points to Australia likely having to adopt systems already fitted to an existing design and by extension establishing the training and logistics chains required to operate, maintain and support new kit not currently in RAN service.

Not a situation which inspires confidence that things are moving in the right direction.

This is where I think the Mogami Batch II's will have an edge over everything else out there. European options on the smaller side, possible to make bigger but that add's risk and time. Daegu batch II will be well out of production and batch III will be winding up and moving onto Batch IV which is expected to be in 4,500 - 5,000 ton range. Daegu III and IV good sizes but a lot of systems including VLS are Korean so how much work would be required to swap K-VLS for Mk 41? let alone other things. Mogami is right sized imo and already uses some systems that we do. Being larger ship more likely be easier to swap thing around be it in design or later on in a refit and it will be in production at time we are looking to get ours.

With all the excitement of new vessels and recent announcements of the surface fleet I can’t help but think what is the plan for building vessels now. Lurssen 6th and final Arafura steel was cut late 2022 so does this mean Civmec yard is empty until potential frigate production? Is Lürssen still undertaking construction of the mcm/survey vessels that was to follow the Arafura. While the surface fleet review mentioned Arafura class vessel was not recommended to be suitable for the mcm/survey role would it be wise to keep Lürssen on to construct these vessels immediately before frigate production starts up later this decade? Using the Corvette c90 hull which is a stretch version of the Arafura a redesign using this larger hull be a consideration for the mcm/survey vessels? It was down selected many years ago for this role and you would presume lurssen has undertaken some design work in this area. What’s people thoughts or understanding as no news on this has been leaked.

Todjaeger

Potstirrer

I believe that ASC, Austal, Civmec and BAE all have facilities at the AMC in Henderson WA in addition to Luerssen Australia, however there has not been word on who will be doing what following the new "plans".With all the excitement of new vessels and recent announcements of the surface fleet I can’t help but think what is the plan for building vessels now. Lurssen 6th and final Arafura steel was cut late 2022 so does this mean Civmec yard is empty until potential frigate production? Is Lürssen still undertaking construction of the mcm/survey vessels that was to follow the Arafura. While the surface fleet review mentioned Arafura class vessel was not recommended to be suitable for the mcm/survey role would it be wise to keep Lürssen on to construct these vessels immediately before frigate production starts up later this decade? Using the Corvette c90 hull which is a stretch version of the Arafura a redesign using this larger hull be a consideration for the mcm/survey vessels? It was down selected many years ago for this role and you would presume lurssen has undertaken some design work in this area. What’s people thoughts or understanding as no news on this has been leaked.

When I look at the satellite imagery of the AMC, I am uncertain which companies/facilities could really be adequate to build frigates TBH, though I am uncertain just how current/accurate the satellite image is. What I measured the buildings which I assume are build halls, Civmec's is ~204 m but does not appear to have a clear path to transport a completed hull into the water. ASC West has what might be a ~110m build hall and a potential route to water. The next largest one belongs to Austal but that is only ~105 m and then there are two others, one belonging to BAE Australia and the other I have not been able to identify, but both of these appear to be less than 100 m in length.

I do recall an announcement by Morrison that a large drydock would be started in ~2023 in Henderson, but the completion date for that IIRC is not until 2030. This makes it look like facility/infrastructure work needs to be carried out before a facility in WA could engage in frigate construction, as well as the need to have a skilled shipyard workforce established there which is capable of doing such work.

To me, the Mogami class fits the bill nicely. Rapid construction, automation, minimal crewing. The main issue as far as I can see is the fact that they have an indigenous AESA and combat system which would have to be left alone. All I can see is trouble if we try to integrate our own equipment with delays and problems. This is the most interesting article I have read on the ship to date. Gives a good insight into the Mogami class. Japan's Futuristic Mogami Frigates: Everything You Need To Know

As far as I am aware LRASM is an Air Launched weapon and can’t be ship launched.I would hope the GPs have at least half there VLS as strike length. For this I would think 32 cells would work. With strike length, it provides the ability to carry LRASMs and Tomahawks. The LRASM will provide a nice range boost and hitting power to the GPs, the Tomahawk ability will provide flexibility to mission planners. If the GPs have a CEC fitted, they could also be used to add SM magazine depth to the Hunters or Hobarts when running with.

And I’ll get my $275 power bill reduction. No matter the brand, the politicians will just say whatever is palatable at the time and come up with excuses later. Given we have had 2 years to get to this point I find that hard to believe.Both Marles and Conroy said, design chosen in 2025, cut steel in 2026, the first in service by the end of the decade and all 3 frigates built overseas in service before the first Hunter in 2034.

It has been proven and tested, not operational yet AFAIK:As far as I am aware LRASM is an Air Launched weapon and can’t be ship launched.

Long Range Anti-Ship Missile (LRASM)

LRASM is a low-risk, multi-service, multi-platform, multi-mission Offensive Anti-Surface Warfare cruise missile.

Under $500m USD each, these really are a little gem. They can be used as the Huon replacements too, as far as I can tell from this article.To me, the Mogami class fits the bill nicely. Rapid construction, automation, minimal crewing. The main issue as far as I can see is the fact that they have an indigenous AESA and combat system which would have to be left alone. All I can see is trouble if we try to integrate our own equipment with delays and problems. This is the most interesting article I have read on the ship to date. Gives a good insight into the Mogami class. Japan's Futuristic Mogami Frigates: Everything You Need To Know

I believe that ASC, Austal, Civmec and BAE all have facilities at the AMC in Henderson WA in addition to Luerssen Australia, however there has not been word on who will be doing what following the new "plans".

When I look at the satellite imagery of the AMC, I am uncertain which companies/facilities could really be adequate to build frigates TBH, though I am uncertain just how current/accurate the satellite image is. What I measured the buildings which I assume are build halls, Civmec's is ~204 m but does not appear to have a clear path to transport a completed hull into the water. ASC West has what might be a ~110m build hall and a potential route to water. The next largest one belongs to Austal but that is only ~105 m and then there are two others, one belonging to BAE Australia and the other I have not been able to identify, but both of these appear to be less than 100 m in length.

I do recall an announcement by Morrison that a large drydock would be started in ~2023 in Henderson, but the completion date for that IIRC is not until 2030. This makes it look like facility/infrastructure work needs to be carried out before a facility in WA could engage in frigate construction, as well as the need to have a skilled shipyard workforce established there which is capable of doing such work.

Here is the Infrastructure strategy from 2020.

Some of the plans were given the green light in 2021.

The building on page 22 is being constructed currently which would allow Silveryachts to move in. The Hall they are currently in next to ASC would probably be reused or dismantled for a new (much larger) fab or consolidation hall like it suggests in the plans. The new Hall approx 170-180mL x 60-70mW

Here is a pic of what the Southern end would look like once complete.

Pic from WA.gov.au

Significant Development Applications

View Part 11B and Part 17 significant development applications listed by local government area.

Attachments

-

320.5 KB Views: 20

Last edited:

Going Boeing

Well-Known Member

As posted by Todjaeger:

”I do recall an announcement by Morrison that a large drydock would be started in ~2023 in Henderson, but the completion date for that IIRC is not until 2030. This makes it look like facility/infrastructure work needs to be carried out before a facility in WA could engage in frigate construction, as well as the need to have a skilled shipyard workforce established there which is capable of doing such work.”

The two concept layouts in this diagram show the location of the proposed dry dock (8). Further details in the article.

https://www.wa.gov.au/system/files/2020-11/2008-075-AMC SILUP-Web.pdf

”I do recall an announcement by Morrison that a large drydock would be started in ~2023 in Henderson, but the completion date for that IIRC is not until 2030. This makes it look like facility/infrastructure work needs to be carried out before a facility in WA could engage in frigate construction, as well as the need to have a skilled shipyard workforce established there which is capable of doing such work.”

The two concept layouts in this diagram show the location of the proposed dry dock (8). Further details in the article.

https://www.wa.gov.au/system/files/2020-11/2008-075-AMC SILUP-Web.pdf

Last edited:

A Top view of the proposed Henderson precinct can also be seen in a document from late last year.

Looks like the second layout is likely.

Page 18.

Looks like the second layout is likely.

Page 18.

Attachments

-

1.7 MB Views: 32

Last edited:

Judging by pictures and a bit of guesstimation if the imagery for the AMC dry dock is accurate and goes ahead as such could be a 350m or more long bit of kit.

Also the Civmec main assembly hall internally is 187m long, The doors alone for entry are 42m? wide and about 60m high so building a Mogami in their or any other ship wont be an issue at all.

Also the Civmec main assembly hall internally is 187m long, The doors alone for entry are 42m? wide and about 60m high so building a Mogami in their or any other ship wont be an issue at all.

The middle bay can build 2 side by side. Civmec use that middle section quite alot though for other projects. Building a frigate Mogami size in the outer bays would be very difficult.Judging by pictures and a bit of guesstimation if the imagery for the AMC dry dock is accurate and goes ahead as such could be a 350m or more long bit of kit.

Also the Civmec main assembly hall internally is 187m long, The doors alone for entry are 42m? wide and about 60m high so building a Mogami in their or any other ship wont be an issue at all.

Not much foresight went into the design it seems. You can build 2 opvs (13m beam) side by side in the outer bays but you can’t build anything wider side by side. If it was 5 or so metres wider either side and the same height across the whole structure, 6 ships up to cruiser size could have been built or maintained at one time. Now just two.

You can see how tight it is in this wa defence vid on youtube.

Last edited:

The BAE and ASC facilities are set up for maintenance. BAE does all the out of water work for the ANZACs and it is an open air hard stand, so weather exposed. ASC does the mid cycle dockings for the Collins in an enclosed shed. There is a lift at each yard (BAEs is 8,000 tonne and the AMC common use one is 12,000 tonne). Both teams are repairers, not builders.I believe that ASC, Austal, Civmec and BAE all have facilities at the AMC in Henderson WA in addition to Luerssen Australia, however there has not been word on who will be doing what following the new "plans".

When I look at the satellite imagery of the AMC, I am uncertain which companies/facilities could really be adequate to build frigates TBH, though I am uncertain just how current/accurate the satellite image is. What I measured the buildings which I assume are build halls, Civmec's is ~204 m but does not appear to have a clear path to transport a completed hull into the water. ASC West has what might be a ~110m build hall and a potential route to water. The next largest one belongs to Austal but that is only ~105 m and then there are two others, one belonging to BAE Australia and the other I have not been able to identify, but both of these appear to be less than 100 m in length.

I do recall an announcement by Morrison that a large drydock would be started in ~2023 in Henderson, but the completion date for that IIRC is not until 2030. This makes it look like facility/infrastructure work needs to be carried out before a facility in WA could engage in frigate construction, as well as the need to have a skilled shipyard workforce established there which is capable of doing such work.

Austal has a series of smaller sheds designed for small ferry and patrol boat builds. Note these are far too small for anything bigger. It has the best ship building crew and competence on the strip, but is hamstrung by its small facilities (note it has bigger yards overseas). Austal has been given a strategic partnership with the Federal Government, which provides it a monopoly for all WA small ship projects (patrol boats and landing craft at the moment). Most importantly, Austal's design team are located here, including for the LCS program. Consider it the brains on the strip.

Civmec has the biggest sheds and the best heavy industrial facility. Their main shed on the south can fit two AWD sized vessels in the mid bay side by side, and the Arafuras would easily fit in the side bays. It's massive and fully digital. Of note, Civmec caters predominantly for the offshore oil and gas, and mining sectors, so Defence is a smaller part of their portfolio. They have very good fabrication/welding capabilities, but limited design. They have access to the CUF ship lift, but note that the CUF wheeled carriers limit movements to 4,500 tonnes. If Austal is the brains, then Civmec is the muscle.

There is also what is known as the Common User Facility, which is owned by the state government. It covers most of the wharf and laydown areas on the southern end. The above 12,000 tonne ship lift is part of it, and a future graving dock would likely form part of this facility. A decision on the graving dock has not yet been made, but there is plenty of discussion. Extending the above metaphore, the CUF is the torso, linking all the individual areas together and providing essential shared services.

With the advent of the eventual Virginia and AUKUS submarines, including the home basing of US and UK vessels in the near future, it is expected that Huntington Ingalls and Babcock will need some space, either in Henderson or on Garden Island (or both). The two have announced a partnership, and the WA Government has released some MOUs, but there are few details at the moment. I would view that any graving dock will be considered as part of what they need.

A graving dock would also allow all the big ships to be maintained (Hunters, oilers etc), as well as American ships such as Burkes.

In regards to consolidation, I would suggest the following is likely to happen:

- Austal will be the lead builder for any future GP frigate and LOCSV and would work with the winning designer.

- Austal will either upgrade their own facilities with new large sheds (less likely), or subcontract Civmec (more likely) for the construction in conjunction with their own workers.

- BAE will remain as is and will continue with all WA ship docking maintenance. It is sized to maintain GP frigates and LOCSV's but Hunters (if any are WA based) will go to the proposed dry dock.

- The CUF will continue to expand and encompas the future graving dock.

- ASC will continue through until the end of the Colins. I am not sure this facility works for nuclear boats (too small and probably lacks the nuclear support infrastructure). I think that will transfer to a graving dock, with the existing facility demobilised.

- Huntington, Babcock and ASC will need to work out their respective roles for subs.