As with any system, it's not so much "mastery" as "mitigate the risk so far as is possible and accepted the residual". And assessments of such things tend to change over time as technology becomes more mature and operators more experienced. At the same time, as HTP torpedos rather dramatically have demonstrated, that assessment is not always accurate and the residual risks are either not well understood, or are accepted when they are still at too high a level for the type of operational situation.

Naval Ship & Submarine Propulsion Systems

- Thread starter rockitten

- Start date

The land-based test was conducted at the Naval Group site of Indret near Nantes, with a submarine operational profile. The test confirmed a submerged duration of up to 3 weeks, the optimization of the maintenance cycle and the performance of the major components of the system. This patrol of 18 days has been conducted in representative operational conditions such as:

- 18 days continuous electrical production from diesel oil reforming

- high pressure (compatible with maximal immersion of the submarine)

- close to submarine environmental conditions and safety requirements

- connected to submarine batteries

- controlled and monitored by only one operator as it will be on board through the Integrated Platform Management System (IPMS)

Last edited:

I watched the video on that late last night and it does look interesting. The comment WRT to combining it with the JMSDF sub batteries, taking the submerged performance out to weeks beyond their current capability was intriguing.

1. I strongly suspect that the Japanese are not going to be interested in this improved hydrogen reforming system that has not been deployed in any navy— the JMSDF have their own submarine tech pipeline planning and growth path for submarine development that does not need this incremental change. Hybridisation with supercapacitors (or ultracapacitors) has also been suggested by Japanese and German studies and research. Supercapacitors offer the advantage that they have a much higher power density than batteries making them more efficient.I watched the video on that late last night and it does look interesting. The comment WRT to combining it with the JMSDF sub batteries, taking the submerged performance out to weeks beyond their current capability was intriguing.

2. I think the French will have better luck selling this AIP system to the Koreans or Canadians — as it better suits their operational profile.

3. The French are selling it as a safer system in terms of hydrogen management, as the 8m long Fuel Cell 2nd Generation Air Independent Propulsion eliminates the use of 130 to 160 tons of hydrides transported by a German fuel cell system. The 4 Type 218SGs will be using hydrides as part of their AIP hydrogen management cycle.

4. The French are so cute, they save weight by taking out the need for hydrides but needs weight and space in the complex hydrogen reforming and Shift reactor to make enable the conversion of water into hydrogen — it’s space packaging really help it to complete with the Swedish stirling AIP engine system — unless Singapore wants to cut the hulls of the Archer class again, the French are out of luck in trying to sell the system to a Swedish and German submarine user. In any submarine design, there are weigh, volume and other design limits — this system is not plug and play for a German or a Japanese submarine design.

Last edited:

I wasn't suggesting that the Japanese would be interested so much, but the idea of marrying the two technologies together is what could be intriguing. The French do gloss over that pure O2 is just as flammable as H and it is also highly toxic as well at 1 atmosphere pressure.

cdxbow

Well-Known Member

Long time since I have done chemistry but I believe pure O2 is neither flammable nor combustible. Sure, a higher concentration causes things to ignite and burn more vigorously, just ask the late Gus Grissom, I know fires on land only started during the Devonian period when atmospheric oxygen got to > than about 15-16%, laying down 'black shale'. Yes, high concentrations of oxygen are toxic, in the old days of NICU many babes went blind because of it.I wasn't suggesting that the Japanese would be interested so much, but the idea of marrying the two technologies together is what could be intriguing. The French do gloss over that pure O2 is just as flammable as H and it is also highly toxic as well at 1 atmosphere pressure.

Oxygen is highly reactive, but it won't burn in open air, as hydrogen will, because it doesn't react with oxygen . . . It's all the other stuff burning in the oxygen that's the problem.I wasn't suggesting that the Japanese would be interested so much, but the idea of marrying the two technologies together is what could be intriguing. The French do gloss over that pure O2 is just as flammable as H and it is also highly toxic as well at 1 atmosphere pressure.

Sandhi Yudha

Well-Known Member

An interesting article about Sweden's A-11 design and the planned three propulsion variants.

Sweden’s Nuclear Submarine: The A-11A ‘Atomic’

Updated. Originally Posted July 12, 2017. Sweden was one of the first countries to pursue a nuclear powered submarine, starting development in 1957. This article summarizes the major features of the nuclear and AIP designs which were part of the journey to the conventionally powered A-11...

www.hisutton.com

I don't think many AIP solutions are plug and play, even if they are sometimes advertised that way, subs have tight margins, and everything needs to be matched. I would imagine the French are chasing new submarine builds. Indian, Malaysian, Brazilian and Indonesian subs, and any new customers.4. The French are so cute, they save weight by taking out the need for hydrides but needs weight and space in the complex hydrogen reforming and Shift reactor to make enable the conversion of water into hydrogen — it’s space packaging really help it to complete with the Swedish stirling AIP engine system — unless Singapore wants to cut the hulls of the Archer class again, the French are out of luck in trying to sell the system to a Swedish and German submarine user. In any submarine design, there are weigh, volume and other design limits — this system is not plug and play for a German or a Japanese submarine design.

The French solution is interesting, because it does remove a lot of "dead weight" in the hydride storage, also there is significant room for improvement, with hydrides there isn't a whole lot more you can do. Its also a bit more flexible as you can build subs with or without AIP fairly easily. Scaling up hydrogen storage has also been an issue with hydride storage. While the dead weight of the reformer is significant, its of a different type, can be integrated into the sub.

Not having hydrogen stored in the submarine is a great advantage. Hydrogen has a range of issues beyond explosive or oxygen displacement.

Oxygen is less problematic. While it can certainly be dangerous, its possible to handle it. Asphyxiant gases there are often no warning signs at all, you just pass out, hydrogen does have a neater habit of going up generally. Hypoxia due to altitude has very different symptoms to that of displacement, displacement you basically go to zero oxygen, and zero CO2 build up. While pure oxygen is toxic at high pressures, it is a nicer option than pure hydrogen. Also you are only storing one gas inside, not two. But again, diesel is really easy to store, refill etc. The key thing is fuel is outside, if you can get the reformer smaller enough it becomes a big win.

I don't think the Japanese are desperate to get in on this. I think the point they are making is that lithium and AIP are complimentary, they don't have to be exclusive. But as lithium gets better, it will make the less effective AIP redundant, generally.

Just playing around with numbers.

Eg 1.5 kg of oxygen per crew member per day, say 60 crew, say 10 day endurance, its about a ton of oxygen per 10 days, just in crew oxygen.

Say a container cylinder 4m x 5 so say 70 cubic metres, so say around 80 tons of liquid oxygen. Wow, crew usage is tiny. Say 18 day endurance, around 3.5t per day.

Say 70t of o2, system has to produce about 8.75 t of hydrogen. So the hydrogen reformer needs to weigh less than about 9 tons of stored Hydrogen. But as hydride, say 70kg per m3, thats around 125m3 of storage. So it needs to be smaller than that ballpark amount. All wild guesses and estimates.

The advantage of this system is put in a bigger liquid oxygen tank.

Last edited by a moderator:

H I Sutton AIP explainer video. Gives a good basic explanation of it, including pro's and con's. He's started a YouTube video channel.

Ananda

The Bunker Group

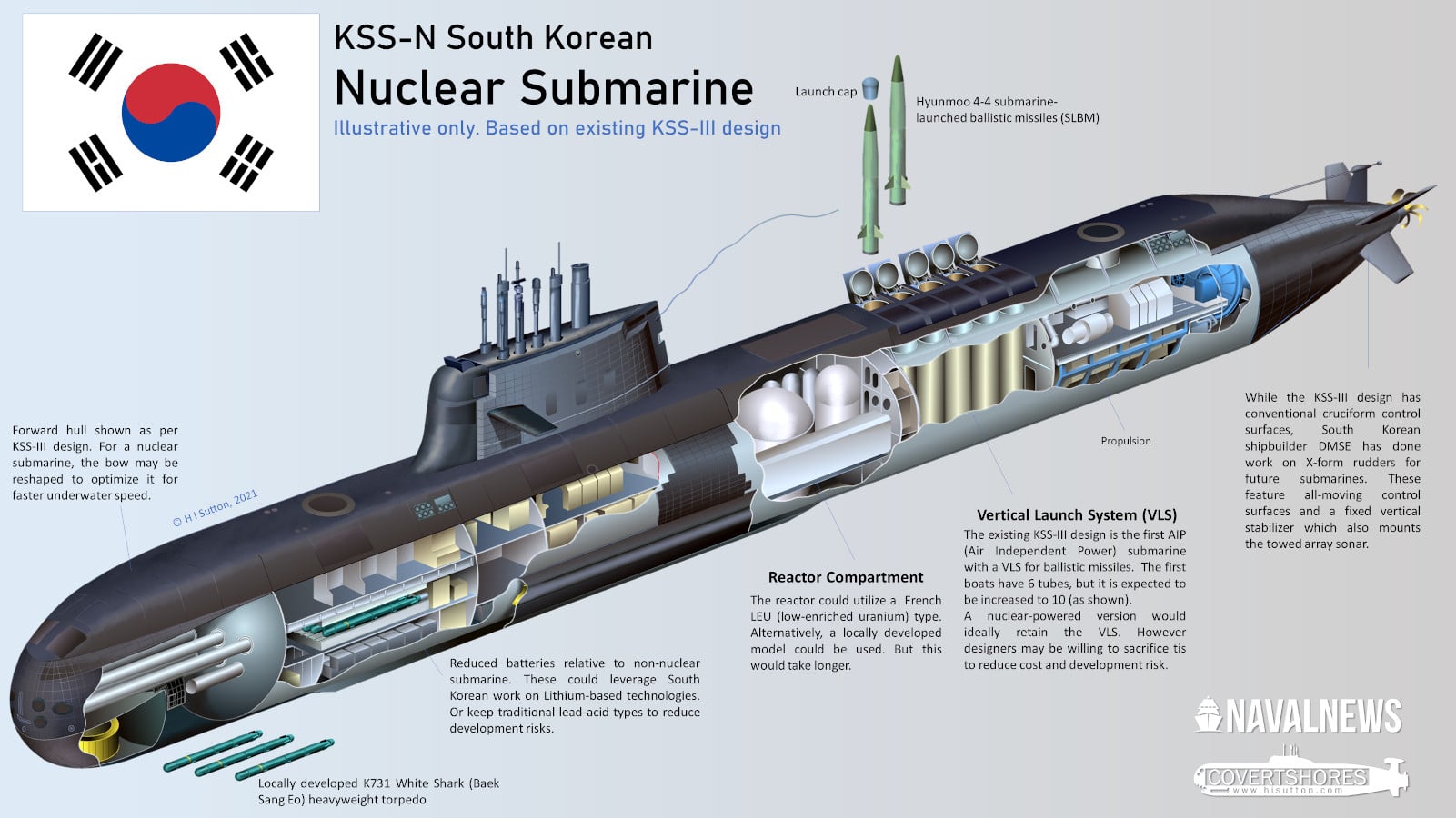

South Korea's First Nuclear Submarine Looks Closer - Naval News

Nuclear submarines offer significant advantages over non-nuclear ones. South Korea as been looking to acquire them for many years and now has the industry to do it.

I'm bit in dilema whether to put this on ROK Navy Thread or in this thread. However decided to put in this thread, cause the topic seems can be on how SSN will be profilerate.

The article is talking on proliferation of SSN after AUKUS. However before AUKUS actually two nation already publickly shown interest for nuclear power Sub, India and Brazil. As the article put Frenchie more inclined providing SSN partnership after Brazil model.

Eventough the article shown potential French offer modified Rubis reactor for ROK, however I don't see a reason ROK can not develop their own low enriched fuel reactor as Brazil does. Off course by working with French developing upgrade Rubis reactor can shorten the times.

Low enriched fuel reactor as we know have handicap compare US and UK High enriched fuel reactor, as interval time needed for refueling once or twice during submarine life time. However as the fuel basically (correct me if I'm wrong) similar grade with civilian nuclear power plant, it will be more beneficial for countries like Brazil or ROK that does mot have weapon grade enrichment facilities, but can do by themselves civilian grade fuel enrichment.

Nuclear power is tounted as most probable and realistic alternative to replace coal power plant as part on sustainable greener alternative. Thus there're more potential countries in future developing nuclear power plant and civilian grade fuel enrichment. This also means potential usage of Low/Civilian Grade compact power plant on Submarine can be happening in more countries.

Developing that kind of SSN from SSK just like French did with Rubis, Brazil does now, and what ROK trying to see the potential. It won't give something in league of US, UK and Russian SSN, bit provide more than SSK.

Last edited:

John Fedup

The Bunker Group

Realistically, a low enriched nuclear reactor is the best way to provide long range and air independent operation. Questionable whether the added capability is worth the cost though, especially for navies that operate regionally.

Nevertheless it will be interesting to see if some of the new compact reactors could be further downsized for sub use and still have sufficient power output.

Nevertheless it will be interesting to see if some of the new compact reactors could be further downsized for sub use and still have sufficient power output.

South Korea’s ADD Develops Critical Technology For Submarine AIP

South Korea’s Agency for Defense Development (ADD) announced on February 22 that it has completed development on “methanol reforming plant technology” for submarine fuel cells.

The technology developed by ADD will allow submarines that use AIP to produce high-purity hydrogen, allowing them to stay underwater for longer periods of time.

South Korea’s ADD develops critical technology for Submarine AIP - Naval News

South Korea’s Agency for Defense Development (ADD) announced on February 22 that it has completed development on “methanol reforming plant technology” for submarine fuel cells.

The technology developed by ADD will allow submarines that use AIP to produce high-purity hydrogen, allowing them to stay underwater for longer periods of time.

South Korea’s ADD develops critical technology for Submarine AIP - Naval News

Attachments

-

45.7 KB Views: 0

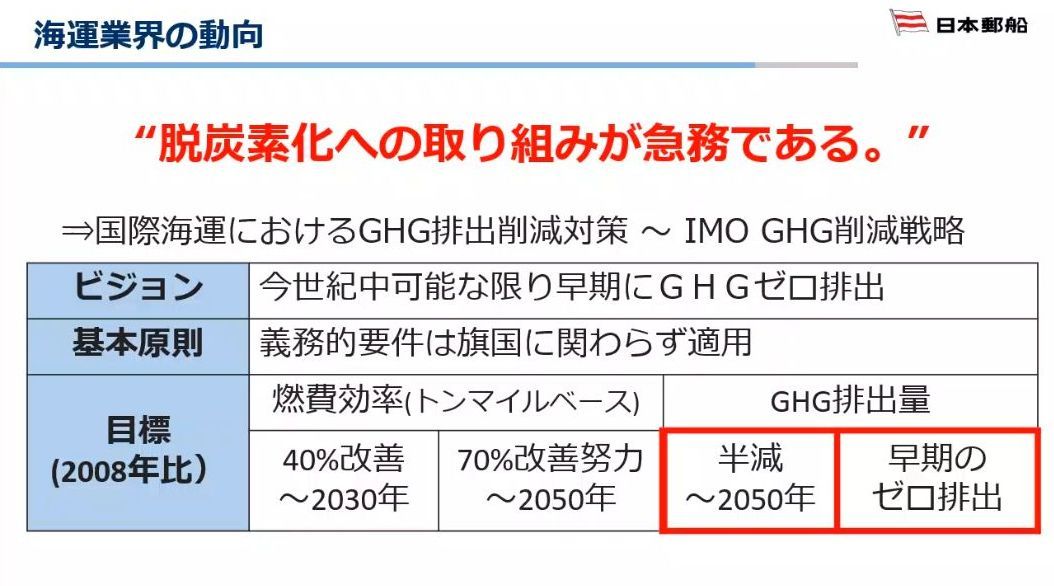

Zero-emission marine transportation, "Japan's first" fuel cell-powered ship to be completed in 2024.

monoist.itmedia.co.jp

monoist.itmedia.co.jp

海運もゼロエミッション、燃料電池で動く「日本初」の船舶が2024年竣工

日本郵船、東芝エネルギーシステムズ、川崎重工業、ENEOS、日本海事協会の5社は、2020年9月1日に「高出力燃料電池搭載船の実用化に向けた実証事業」を開始した。水素で発電する燃料電池を船舶で使用し、温室効果ガスの排出削減に取り組む。同日、5社合同の記者説明会を実施し、燃料電池船の実証実験における意義と概要を説明した。

Is it possible to have an English translation of the article please. Few of us speak Japanese.Zero-emission marine transportation, "Japan's first" fuel cell-powered ship to be completed in 2024.

海運もゼロエミッション、燃料電池で動く「日本初」の船舶が2024年竣工

日本郵船、東芝エネルギーシステムズ、川崎重工業、ENEOS、日本海事協会の5社は、2020年9月1日に「高出力燃料電池搭載船の実用化に向けた実証事業」を開始した。水素で発電する燃料電池を船舶で使用し、温室効果ガスの排出削減に取り組む。同日、5社合同の記者説明会を実施し、燃料電池船の実証実験における意義と概要を説明した。monoist.itmedia.co.jp

The article specifically refers to this project of NYK which started with feasibility studies back in 2020:Is it possible to have an English translation of the article please. Few of us speak Japanese.

Demonstration Project Begins for Commercialization of Vessels Equipped with High-power Fuel Cells | NYK Line

Provides information about [News Releases]. The NYK Group is a global logistics enterprise centered on various forms of marine transport, such as global logistics business and bulk energy transportation, among many other related businesses.

The main new thing compared to the 2020 press release i guess is the new design of the ferry on page 3 of the article.

NYK is part of the Mitsubishi conglomerate and operates a fleet of about 800-900 large cargo and passenger ships as well as - through subsidiary companies - having significant stakes in operating port infrastructure and container terminals both in Japan and globally (US west coast and China in particular).

Thanks, that looks quite interesting. It it works as advertised it would have naval implications.The article specifically refers to this project of NYK which started with feasibility studies back in 2020:

The project is about developing a small coastal passenger boat (100 PAX) with a fuel-cell engine in order to study integration of hydrogen into a business workflow. It is planned to build a demonstrator in 2023 and run a 6-month monitored operative phase for business implementation in H2/2024. NYK has a couple parallel projects along similar lines, e.g. also for a similar-size (bigger) ammonia-powered tugboat to be built in 2023.

Demonstration Project Begins for Commercialization of Vessels Equipped with High-power Fuel Cells | NYK Line

Provides information about [News Releases]. The NYK Group is a global logistics enterprise centered on various forms of marine transport, such as global logistics business and bulk energy transportation, among many other related businesses.www.nyk.com

The main new thing compared to the 2020 press release i guess is the new design of the ferry on page 3 of the article.

NYK is part of the Mitsubishi conglomerate and operates a fleet of about 800-900 large cargo and passenger ships as well as - through subsidiary companies - having significant stakes in operating port infrastructure and container terminals both in Japan and globally (US west coast and China in particular).

Posted previously on the RCN thread. Interesting article on the use of micro-reactors in small displacement submarines.

John Fedup

The Bunker Group

I had a chance to read over this paper. Certainly SMRs might be an option but the paper correctly points out the challenges. Integration of any of the listed designs into a sub involves major R&D development. How many current sub operators could the RCN realistically partner with for a ocean range SSMN? Even a littoral SSMN might find view navies willing to share the costs. I do like the redundancy of possibly having having two reactors. As these MNR are small and use LEU, quick refueling might just be a reactor swap out. It will be interesting to see if this idea goes anywhere. Hope it does, both for commercial power and subs. My guess is the cost of this won't be much less than an AUKUS SSN, especially if the RCN is the only player.Posted previously on the RCN thread. Interesting article on the use of micro-reactors in small displacement submarines.

Ananda

The Bunker Group

If we are talking on what potential alternative nuclear tech for Naval used, we can also look on Thorium development.

Molten Salt Reactors: Maritime’s Nuclear Option

Accelerated Mobile Pages Project

Modular Molten Salt Nuclear Power for Maritime Propulsion

Evolving modern modular molten salt nuclear technology incurs comparatively lower cost while using a...

It is for me thorium despite all the tech challenges still faced for commercial implementation, but lately on last few years already got more and more traction. Just one alternative on nuclear propulsion for naval use that can be think off.

Last edited: