Wherever Soldiers go, shelters must go, too. These shelter systems must not only protect and provide comfort; they must also be as energy efficient as possible. Every time a base camp needs fuel delivered, that camp and its warfighters are exposed to vulnerabilities.

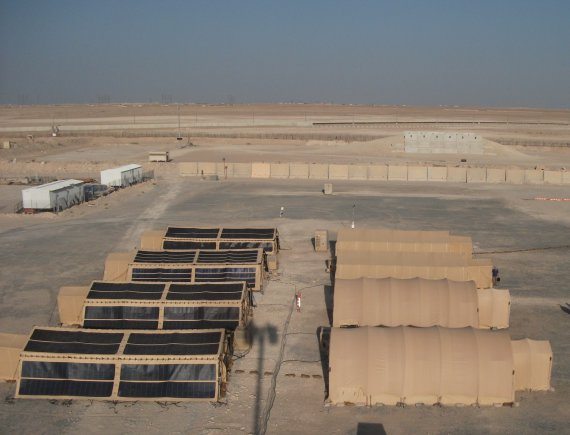

That’s why a group of shelters were sent to the Southwest Asia Area of Responsibility to be tested by both the Army and Air Force recently as part of the “Advanced, Energy-Efficient Shelter Systems for Contingency Basing and Other Applications” program.

“It’s not until you actually put it in an operational environment where you can really have a good assessment of what will work and what won’t work for the Army,” said Amy Klopotoski, contingency basing science and technology lead at the Natick Soldier Research, Development and Engineering Center.

Most of the shelters being tested are 20 feet wide by 32 feet long, and are equipped with various energy-saving technologies that must adapt to the environments warfighters face: median temperatures ranging from minus 25 to 120 degrees Fahrenheit in all sorts of weather.

Tent fabrics have to be durable, mildew resistant, flame resistant, and capable of blackout, which is why “you have multiple layers with multiple different functions in these textiles,” said Klopotoski.

Klopotoski explained that advanced materials such as additional reflective layers, “basically aluminized film,” were added onto pre-existing shelter fabrics. Low-emissivity coatings are another product being tested, specifically for durability. This coating will also reflect the sun’s energy away from the shelter.

All tents were outfitted with more advanced thermal insulation, also developed by NSRDEC, designed to reduce the power required to heat and cool the shelters without increasing weight and bulk. Every tent also had integrated solar shades that reduce solar load and the build-up of heat within the tents, without increasing the shelter’s footprint.

“The NSRDEC provided many technologies utilized in the tests,” said Klopotoski. “The reduction in energy demand will be achieved through a combination of technologies.”

The joint Army/Air Force team hopes to reduce that demand by at least 50 percent through the use of solar shades, photovoltaics, advanced materials and coatings.

Besides energy reduction, there will also be less weight and extra equipment warfighters would need to support sustainable living.

“Currently, we field each 640-foot-square shelter with one five-ton (Portable Environmental Control Unit), where with these shelters, we have two 640-foot-square shelters being cooled with one five-ton ECU,” said Klopotoski.

This reduction eliminates 2,200 pounds and 4,160-square-feet of equipment, as well as reducing up to 40 kilowatts of energy consumption on a 150-man camp.

One shelter is even outfitted with photovoltaic modules, balance of systems electronics to make the power generated usable, and battery backup for storage and future use that was developed through NSRDEC projects.

“The photovoltaics generate power for lights and subsidiary equipment, which reduces the need for diesel-fueled generators,” said Klopotoski.

Reducing the need for diesel fuel cuts down on energy consumption, cost and the need for refueling, which will mean fewer Soldiers transporting fuel on the roads.

Previous similar tests could only be run if NSRDEC personnel physically came to the site every 30 days to download data; now that data can be accessed remotely in real time.

“The data collection equipment measures the temperatures at all of the different layers of the shelters, including outside of the solar shade, in-between the solar shade and tent, the tent surface, and internal temperatures, as well as airflow inside the tent,” said Klopotoski. “We are also measuring the fuel being consumed and the power usage of all of the equipment.”

This intensive testing will be completed in November. Following this testing will be tests at a cold-weather location to collect the same type of data in a minus 25 degree Fahrenheit environment.

The results of this data collection will assist both the Army and Air Force as they seek to provide warfighters with the best technological advances possible.

NSRDEC is part of the U.S. Army Research, Development and Engineering Command, which has the mission to develop technology and engineering solutions for America’s Soldiers.

RDECOM is a major subordinate command of the U.S. Army Materiel Command. AMC is the Army’s premier provider of materiel readiness — technology, acquisition support, materiel development, logistics power projection, and sustainment — to the total force, across the spectrum of joint military operations. If a Soldier shoots it, drives it, flies it, wears it, eats it or communicates with it, AMC provides it.