Scientists at Tokyo Institute of Technology (Tokyo Tech) developed a new methodology that allows researchers to assess the chemical composition and structure of metallic particles with a diameter of only 0.5 to 2 nm. This breakthrough in analytical techniques will enable the development and application of minuscule materials in the fields of electronics, biomedicine, chemistry, and more.

The study and development of novel materials have enabled countless technological breakthroughs and are essential across most fields of science, from medicine and bioengineering to cutting-edge electronics. The rational design and analysis of innovative materials at nanoscopic scales allows us to push through the limits of previous devices and methodologies to reach unprecedented levels of efficiency and new capabilities. Such is the case for metal nanoparticles, which are currently in the spotlight of modern research because of their myriad potential applications.

A recently developed synthesis method using dendrimer molecules as a template allows researchers to create metallic nanocrystals with diameters of 0.5 to 2 nm (billionths of a meter). These incredibly small particles, called “subnano clusters” (SNCs), have very distinctive properties, such as being excellent catalyzers for (electro)chemical reactions and exhibiting peculiar quantum phenomena that are very sensitive to changes in the number of constituent atoms of the clusters.

Unfortunately, the existing analytic methods for studying the structure of nanoscale materials and particles are not suitable for SNC detection. One such method, called Raman spectroscopy, consists of irradiating a sample with a laser and analyzing the resulting scattered spectra to obtain a molecular fingerprint or profile of the possible components of the material.

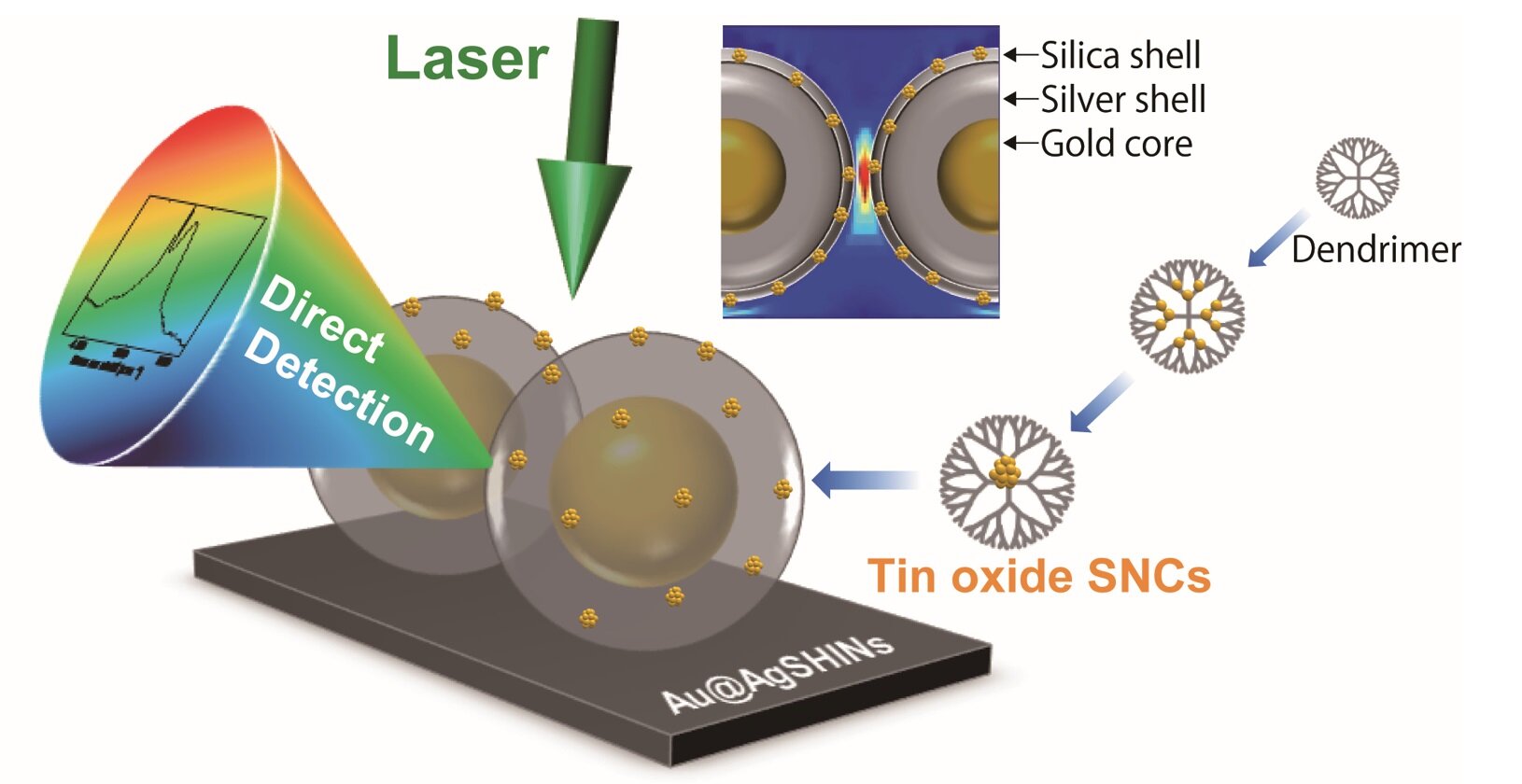

Although traditional Raman spectroscopy and its variants have been invaluable tools for researchers, they still cannot be used for SNCs because of their low sensitivity. Therefore, a research team from Tokyo Tech, including Dr. Akiyoshi Kuzume, Prof. Kimihisa Yamamoto and colleagues, studied a way to enhance Raman spectroscopy measurements and make them competent for SNC analysis (Figure).

One particular type of Raman spectroscopy approach is called surface-enhanced Raman spectroscopy. In its more refined variant, gold and/or silver nanoparticles enclosed in an inert thin silica shell are added to the sample to amplify optical signals and thus increase the sensitivity of the technique. The research team first focused on theoretically determining their optimal size and composition, where 100-nm silver optical amplifiers (almost twice the size commonly used) can greatly amplify the signals of the SNCs adhered to the porous silica shell.

“This spectroscopic technique selectively generates Raman signals of substances that are in close proximity to the surface of the optical amplifiers,” explains Prof. Yamamoto.

To put these findings to test, they measured the Raman spectra of tin oxide SNCs to see if they could find an explanation in their structural or chemical composition for their inexplicably high catalytic activity in certain chemical reactions. By comparing their Raman measurements with structural simulations and theoretical analyses, they found new insights on the structure of the tin oxide SNCs, explaining the origin of atomicity-dependent specific catalytic activity of tin oxide SNCs.

The methodology employed in this research could have great impact on the development of better analytic techniques and subnanoscale science. “Detailed understanding of the physical and chemical nature of substances facilitates the rational design of subnanomaterials for practical applications. Highly sensitive spectroscopic methods will accelerate material innovation and promote subnanoscience as an interdisciplinary research field,” concludes Prof. Yamamoto.

Breakthroughs such as the one presented by this research team will be essential for broadening the scope for the application of subnanomaterials in various fields including biosensors, electronics, and catalysts.