A versatile new suite of modular appliances promises to make feeding Soldiers in the field a more energy-efficient, cleaner, cooler and quieter process.

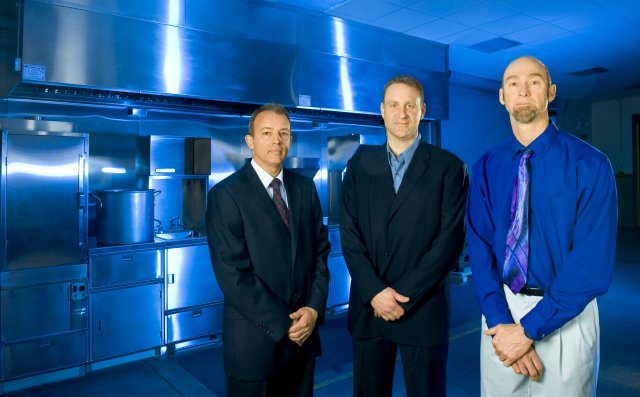

Product Manager Force Sustainment Systems, or PM FSS, and the Natick Soldier Research, Development and Engineering Center’s Department of Defense Combat Feeding Directorate have teamed up to produce prototypes of the new appliances — powered by JP-8 fuel — that can be combined, split up and located in any setting from a mobile kitchen to a building.

“We hope to actually be able to utilize these across all our platforms of all sizes,” said Tim Benson, assistant product manager, PM FSS. “Right now, it’s being evaluated in base camp applications.”

The kitchen in a new Force Provider, or FP, 100-person camp will be outfitted with the new appliances, said Benson, “so that they can be directly compared in terms of what fuel-efficiency gains there are and how that helps operational energy savings.”

The first FP modular kitchen could be completed by May 2013.

“We’re trying to position the Army for a replacement kitchen to completely replace the (Mobile Kitchen Trailer) with what we call the Battlefield Kitchen,” said Benson, “and that would be based around these modular appliances.”

According to Benson, Containerized Kitchens could also be updated with the new appliances.

“These appliances could be used on any kitchen platform,” said Tony Patti, team leader, Equipment and Energy Technology, Combat Feeding. “Their versatility allows you the flexibility to use them in any situation.

“In addition, the modular concept has universal components. That allows you to configure them for different variations. They’re also able to operate independently, so they can stand on their own for any mission need.”

“You can quickly assemble a kitchen complete with ventilation inside of a building using these appliances,” said Glenn Doucet, project engineer, Food Service Equipment Team, Combat Feeding. “One of the main reasons we went to this is because they want to bring equipment into buildings.”

Each appliance consists of what Doucet called “the same basic building blocks”: a base, drawer module, cabinet module, heater module, vent hood module, and appliance module. They are easily broken down and moved.

“You can splinter them down off of a kitchen trailer platform and have them all be self-sustaining or self-supporting,” Patti said.

The new appliances would replace the venerable Modern Burner Unit, or MBU, a proven, rugged field appliance. But MBU-based kitchens lack the interchangeability of the modular suite across various platforms, and the current kitchens can produce an average of 85 decibels of noise and reach temperatures of 150 degrees Fahrenheit. The modular appliances are much quieter and individually vented to pull the heat and exhaust gases out of the kitchen space.

“We have a closed-combustion chamber that transfers the energy to the cook surface more efficiently, and (it) also offers quiet operation, and most importantly, it will take the combustion effluent and duct it out of the kitchen,” Patti said. “It provides clean, quiet combustion that rivals common natural gas or propane appliances typically found in residential homes.”

The goal, said Doucet, is a kitchen that can stay within 10 degrees of the outside temperature.

“In the past, we have tried to cool the kitchens, but there was just too much heat,” Doucet said. “Our new approach is to produce less waste heat and get more of that heat out with an improved ventilation system.”

Sergeant First Class Scott Sickels, the Combat Feeding Research, Development, Technology and Engineering NCO, lauded the inclusion of a “thermal control unit” in the modular appliance suite, the new tilt skillet and the ability of the closed combustion system to vent exhaust gases and heat.

“These modular appliances do not require a cook to stand there and manually turn the dial up and down,” Sickels said. “They automatically sense the temperature and turn the burner on and off as appropriate. The tilt skillet is a new appliance that is not currently available on any field kitchen platform and is a great addition. These modular appliances will greatly enhance the cook’s ability to perform their mission of feeding today’s war fighters.”

The modular appliances, in development for two years, could use as little as 50 percent of the fuel now needed by appliances that are currently fielded. They require about the same amount of electricity as a light bulb.

“We’ve run these appliances on solar panels in the summertime,” said Patti of the modular suite. “It uses so little power. You can even operate on batteries and let the solar panels do the recharging.”

Reducing weight and cost will be the next goal, if it makes economic and functional sense.

“We’ll probably switch to aluminum on non-structural components someday that not only will reduce weight, but will also reduce cost, as well,” Patti said. “We’re excited to take on those challenges going down the road.”

It’s a road that leads to a future with better, more efficient field feeding.