Nobody works on more Army helicopters than Corpus Christi Army Depot, so when it comes to repair and overhaul, they cut a lot of metal.

Gone are the days of hunching over a pristine sheet of metal meticulously drilling holes and patterns by hand. Now, depot artisans are a step closer to automating the entire sheet metal manufacturing process at Corpus Christi Army Depot, or CCAD.

“This automation will increase quality, reduce manufacturing times and allow one standard time allotted for cutting and deburring patterns and formatting aircraft sheet metal parts manufactured at CCAD,” said Roland de la Fuente, a sheet metal mechanic supervisor.

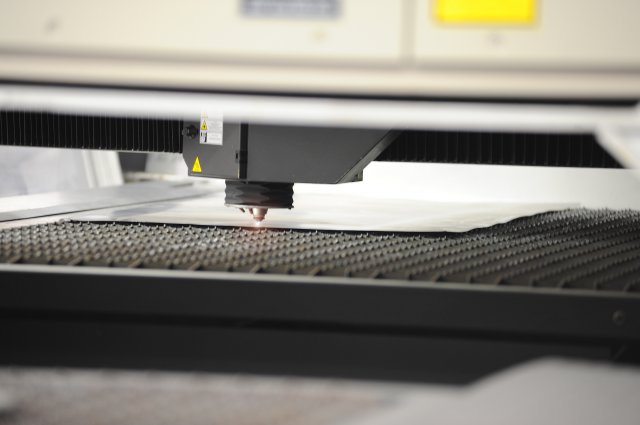

Their new laser was put into production in 2010, but it went virtually unnoticed next to the bus-sized fluid cell press that normally steals the show.

“It takes having to see the laser in action to really get the ‘wow factor,'” said de la Fuente of the new laser cutter.

The fixture is described by the manufacturer as a high performance linear motor that delivers high-speed cutting for fast, continuous processing of high quality parts.

The laser cutting fixture is used to cut sheet metal patterns that are later formed with the fluid cell flex press or power brakes before they are put on a helicopter.

With a cutting speed of 40 meters per minute, the laser is faster than producing patterns by hand. The laser can cut through several thicknesses of different material, including plate steel, stainless steel and aluminum. Patterns are guaranteed to cut within tolerance, with a repetitive accuracy of .0008 ten thousandths of an inch.

Aircraft sheet metal mechanic Jeremy Garcia has noticed a big difference in the time it takes to produce parts since they started using the new fixture.

“It took us 24 hours to manufacture by hand,” he said. “Now manufacturing takes only eight hours.”

In the past, a sizeable product like a UH-60Black Hawk helicopter bulkhead required the part to be pressed by hand in multiple sections. It all changed with the new fixture. The laser cutter can cut a pattern in as little as five minutes.

“It’s one run and that’s it,” said Garcia.

The advantage of the new laser comes with the computer technology. The laser is controlled using a computer and CADMAN software. The CADMAN is a computer-aided drafting program that specifies the laser’s cutting path.

“The laser is the first member of a fabrication cell I am developing to support the fluid flex cell,” said de la Fuente. Plans for another laser, a turrent punch and two power breaks, all using the same CADMAN software, are in the works.

By utilizing the same CADMAN software, all the machines will be able to community with each other. According to LVD, the CADMAN programming software offers offline integration of the key sheet metalworking processes of laser, punching and bending.

“This will allow the artisans to create pattern-cutting and forming programs at the instant the flat patterns is drafted in CADMAN,” said de la Fuente. “The artisan can then transfer the pattern-cutting program to a punch or laser or even transfer a brake-forming program to the power brakes without having to leave his seat.”

“The laser has performed superbly thus far,” he said.

The laser cutting fixture and the subsequent automation implementations will allow CCAD to schedule accurately and allow the training of a more technologically-proficient workforce to meet unpredicted surges in demand.