The U.S. Army-led Joint Light Tactical Vehicle, or JLTV program, is beginning a 33-month Engineering and Manufacturing Development phase, also known as EMD.

The EMD phase is designed to test and prepare the next-generation vehicles for a Limited User Test, Capabilities Production Document and Milestone C procurement decision in fiscal year 2015, service officials said.

“The JLTV incorporates a whole new generation of automotive technology,” said David Bassett, deputy program executive officer, Combat Support and Combat Services Support, known as PEO CS & CSS.

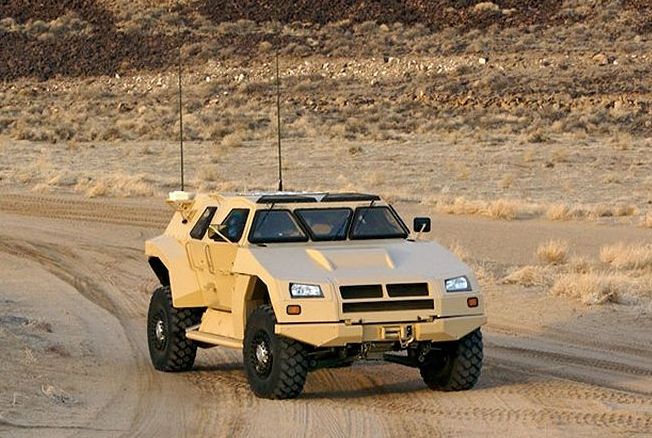

The Army-Marine Corps JLTV program, designed to develop a new light tactical vehicle engineered with an unprecedented blend of protection, performance and payload capability complete with improvised explosive device, or IED, protection, networking capability, and on-board power generation, recently awarded three EMD-phase contracts worth roughly $65 million each to Lockheed Martin, Oshkosh Defense and AM General.

The JLTV program worked with engineers, requirements experts with the Army’s Training and Doctrine Command and industry partners during the TD phase to identify and, in some cases, trade-off less crucial requirements in order to lower the per-unit vehicle price to a range of $250,000 and still develop substantial leap-ahead capability. These cost-informed trades, along with the integration of mature technologies, allowed the JLTV program to shorten the EMD phase from 48 to 33 months, JLTV program officials said.

“The JLTV program capitalized on the benefits of competitive prototyping during the TD phase, where the efforts of multiple vendors substantially improved the fidelity of the designs, and increased confidence in operational performance,” said Robert Schumitz, deputy program manager.

NEW AUTOMOTIVE TECHNOLOGY

The JLTV represents the next-generation of automotive technology in a number of key respects, such as the ability to design a light tactical, mobile vehicle with substantial protective ability to defend against IEDs, roadside bombs and other threats, Bassett explained.

“The vehicle is designed from the ground up to be mobile and get you to the fight with a level of underbody protection equivalent to the original MRAP-ATV (mine resistant, ambush protected — all-terrain vehicle) vehicle standards. Also, the vehicle is being designed with modular armor, so that when the armor is not needed, we can take it off and bring the weight of the vehicle down to drive down the operating costs,” Bassett said.

With a curb weight of roughly 14,000 pounds, the JLTV will provide protection comparable to the 25,000-pound M-ATV, thus combining the mobility and transportability of a light vehicle with MRAP-level protection.

“I remember transitioning from the jeep to the Humvee as a young enlisted Soldier, because our needs had changed. Now warfare and our Soldiers needs have changed again. By the time we put extra armor on the Humvee to meet today’s threats, there wasn’t any payload (weight) capacity left. And, while the MRAP had the armor and some payload, it wasn’t well equipped to maneuver. The intent with JLTV is to have a vehicle with MRAP-level armor in some places, but also still with payload and maneuverability,” said incoming JLTV Joint Program Manager Col. John Cavedo.

When compared with earlier light tactical vehicle models such as the Humvee, the JLTV is being engineered with a much stronger, 250 to 360 horsepower engine and a 570-amp alternator able to generate up to 10 kilowatts of exportable power. In fact, due to the increase in need for on-board power, the JLTV testing during the EMD phase will include the integration of a suite of Command, Control, Communications, Computers, Intelligence, Surveillance and Reconnaissance, or C4ISR, kits and networking technologies, Bassett explained.

“We expect to see a 10 to 15-percent improvement in fuel economy just by going to a modern fuel-injected, digitally-controlled engine and have a curb weight that still meets Army and Marine Corps mobility requirements,” he explained. “The JLTV will be designed with enough on-board power to support the Army’s future network and be able to take advantage of the latest generation of diesel engine technology to maximize fuel economy.”

The in-vehicle network approach is grounded in “open architecture,” meaning that information technology systems and electronics will all be built to commercial technical standards ensuring maximum interoperability. JLTV is aligning with the new VICTORY standards, which will enable a single computer or system to run a host of interoperable applications and functions.

With the JLTV architecture, the vehicle will be able to streamline and more easily exchange and transmit information while ensuring that the maximum number of programs and applications are possible on any given computer or display screen.

EMD PHASE

The first part of the EMD phase will be a build phase wherein industry vendors are given nine months to refine their designs and deliver 22 trucks, complete with corresponding blast hulls and armor coupons to the government, Bassett said.

This will be followed by three months of contractor testing and then a series of formal government tests in key areas such as ballistic and blast testing, reliability and performance assessments, corrosion testing and a series of mobility and transportability evaluations, Bassett explained.

Affordability remains a large part of the calculus regarding the JLTV program, so the Army-Marine Corps program office encourages competition among vendors and expects to maintain a cost-conscious approach. In fact, a competitive procurement model, which will continue to inform the effort through the EMD phase, has greatly helped the maturation of the program thus far, Bassett said.

The JLTV is being built as a single truck in two primary configurations, a four-door platform called the Combat Tactical Vehicle and a two-door platform called a Combat Support Vehicle. The four-door platform will include a Heavy Gun Carrier and Close Combat Weapons Carrier variants designed to carry weapons such as a .50-cal machine gun, TOW missile and conduct mounted patrols and convoy escort missions, among other things. The Combat Tactical Vehicle will be able to carry 3,500 pounds of payload.

All of the JLTVs will be configured with what is called Variable Ride-Height Suspension, described as the ability to raise and lower the suspension to meet certain mission requirements such as the need to raise the suspension in high-threat areas and lower the suspension so that the vehicles can be transported by maritime preposition force ships. Also, the JLTV will be able to sling-load beneath a CH-47 Chinook helicopter under standard conditions, Bassett said.

The goal at the end of the EMD phase will be for the Army-Marine Corps program to down-select a single vendor and move into Low Rate Initial Production, or LRIP, by 2015, Bassett said. The plans call for three years of LRIP, to be followed by five years of full-rate production, resulting in an incremental delivery of the vehicle. The Army plans to acquire roughly 50,000 JLTVs and the Marine Corps plans to procure about 5,500.