A British industry team led by BAE Systems has completed the final tests on the ejection or escape system for all variants of the F-35 Lightning II combat aircraft. The system has been certified as safe for flight after a series of rigorous tests. The escape system, used in emergency situations, ensures pilots can eject safely and will be fitted to all 3000+ F-35 aircraft which will be flown by armed forces across the globe.

The system has been tested to its limits, as a full scale front section of the aircraft, complete with ejection seat and mannequin was launched at speeds in excess of 600 mph down a test track. More than 30 ejection seat tests have been completed in the UK, France and the USA.

Witnessing the final test which took place at Martin Baker’s facility at Chalgrove Airfield in Oxfordshire, BAE Systems’ Test Manager Rick Whittaker commented “Ejecting from an aircraft like F-35 typically takes no more than three seconds from the time the ejection handle is pulled to the pilot being on a parachute. You can imagine how quickly everything happens. Incredibly, during the tests up to 900,000 measurements were recorded every second and I am pleased to say the systems performed really well.”

Chris Garside, BAE Systems’ Chief Engineer on the F-35 programme added: “Achieving this certification marks the culmination of several years’ hard work across an integrated team and across a range of functions. It’s a major achievement. The system has consistently performed as expected through a progressive series of tests. The escape system standard that underwent the final tests is now being implemented into the production aircraft.”

The industry team included BAE Systems as prime sub-contractor to Lockheed Martin on the F-35 programme and the Martin Baker Aircraft Company who are responsible for producing the US16E ejection seat, a derivative of the highly successful Mk 16 family of seats. Pacific Scientific Energetic Materials Company will provide the transparency removal system which cuts the canopy for the seat to exit and Honeywell will deliver vital Life Support systems for the pilot.

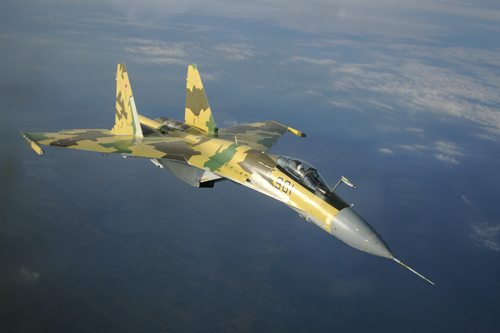

The three variants of the F-35 Lightning II are being developed to meet the different performance requirements of the US and UK armed forces. The Carrier Variant (CV) is being designed for the US Navy and the UK and must cope with the demands of the catapult launches and arrested landings on the large US aircraft carriers. The Conventional Take Off and Landing (CTOL) variant will meet the needs of the US Air Force. Finally the Short Take Off and Vertical Landing (STOVL) variant is being developed to meet the operational requirements of the US Marine Corp.

BAE Systems Contribution to F35 Programme

BAE Systems is responsible for the design and delivery of the aft fuselage and empennage (tails and fins) for each F-35 variant, as well as key areas of the vehicle and weapon systems, in particular the fuel system, crew escape, life support system and prognostics health management integration. The Company also has significant work share in autonomic logistics, primarily on the support system side, and is involved in the Integrated Test Force, including the systems flight test and mission systems.