The U.S. Army’s Benét Laboratories, which is collocated on the Watervliet Arsenal, recently announced that it has achieved a significant milestone in the research and development of an extended-range 120mm mortar ballistic test cannon that if fielded, will greatly increase the survivability of U.S. infantrymen.

“After several years of research and design, we now have a 120mm mortar test system that has just left the arsenal en route to the U.S. Army Yuma Proving Ground in Arizona for live-fire testing,” said Robert Cooley, a mechanical engineer with Benét Labs. “This weapon will allow us to test a number of new technologies needed to support extended range mortars and support improvements to ammunition and propellants.”

The arsenal’s production of 60mm, 81mm, and 120mm systems used by the Army has greatly increased in recent years as the battles in mountainous Afghanistan required a highly mobile, responsive, and high-altitude delivery system. Although the effectiveness of these systems is well documented in recent combat operations, their technology is more than 30 years old, Cooley said. Improved, lighter, 60mm and 81mm systems have started reaching the field over the last few years.

Paul Koelbel, a fellow Benét Labs mechanical engineer and lead designer for the 120mm extended-range system, said that simply designing a tube that will fire a mortar round farther is only a small part of all the research and design that is required.

Although the requirements for the improved range mortar and ammunition still must be approved by Army program managers, this and future tests, is a significant step toward increasing the survivability of the nation’s troops, said Francesco Tropiano, a Benét Labs’ mechanical engineer.

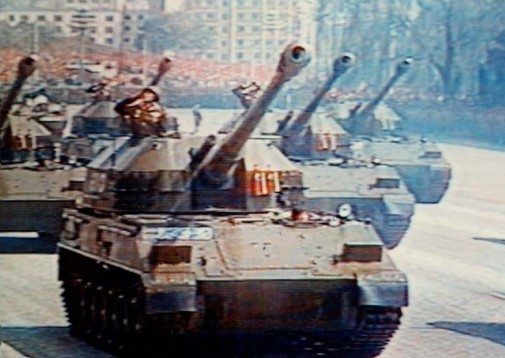

“We are seeing in a number of armies throughout the world using a variety of mortar systems that have capability that exceed our legacy systems,” Tropiano said. “This system will close the gap and put our infantryman on par with the best mortar systems in the world.”

In addition to working closely with the Army’s ammunition community, Benét Labs also works hand-in-hand with arsenal manufacturing. The Watervliet Arsenal is the only place in the Department of Defense where those who do research and design work within a five-minute walk of those who will machine the design. This synergy provides an environment of rapid response to the emerging needs of today’s Army.