Just as sunglasses protect the wearer’s eyes from the ultraviolet rays of the summer sun, some materials protect eyes and sensors from laser devices. U.S. Army Research Laboratory scientists are looking at findings from university partners to determine which materials provide the most effective protection against lasers.

“Bringing new levels of protection from lasers to the Soldier requires the development of advanced materials as well as new optical system designs,” said Andy Mott, Laser Protection team leader, U.S. Army Research Laboratory, or ARL.

ARL is working closely with the U.S. Army Tank Automotive Research Development and Engineering Center, or TARDEC, to characterize and marry-up the materials to existing Army ground vehicles.

“The lab focuses on materials science, modeling, and simulation, but it takes TARDEC to pull it together and demonstrate to a Program of Record,” Mott said.

TARDEC not only works with ARL, but also the Night Vision Laboratory at the Communications-Electronics Research, Development and Engineering Center, known as CERDEC, “… to tap into their optical systems performance expertise,” said Robert Goedert, TARDEC program manager.

CERDEC “exploits sensor and sensor suite technologies to see, acquire, and target opposing forces, day or night, under battlefield conditions,” according to the organization website.

“Laser protection development has been a continuous cycle of research, testing, revising parameters, performance modeling, and then feeding it back through the cycle to develop system designs, which are then prototyped for demonstration,” Goedert said.

“It takes a lot of collaboration to transition technology into a vehicle [program manager’s] acquisition cycle,” Goedert said. “The ground combat system’s parameters need to be understood by each of the organizations involved in the design process to ensure successful integration of the new hardware. The partners on this project have been collaborating for over seven years, but the pinnacle of the effort is taking place right now with upcoming outdoor field tests that will embed ARL materials into TARDEC hardware.”

ARL has been developing laser damage protection materials for mounted ground vehicles and individual dismounted Soldiers for nearly 20 years.

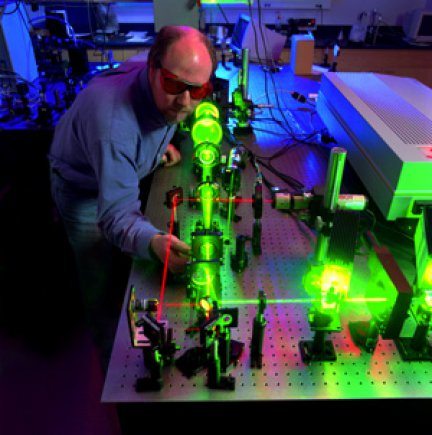

“The lab’s niche — characterization of complex molecules with nonlinear properties, delivering the kind of materials that would allow natural light through, but block any laser light — is what ARL brings to the project,” Mott said.

“Lasers of varying pulse width and wavelength are being developed every day,” Mott continued. “We protect against the known threats, and unknown ones. We develop protection for electronic sensors of the future, as well as the sighting systems of today.”

A laser could permanently incapacitate, or blind cameras without laser protection. If all of a sudden a video camera in your military vehicle goes black, completing your mission might be more difficult, Mott said.

“Lasers could also inflict damage to Soldiers ranging from short-term pain and disorientation to lifelong blindness,” he said. “It may not be deadly, but it can be debilitating, and it may reduce overall survivability.”

As the battlefield becomes more technologically advanced, new dangers to security and safety will arise. Laser protection counters some of these new dangers, Mott said.

ARL is working with other Army organizations, like TARDEC, to develop both long- and short-term ways to meet the challenge.

ARL, TARDEC and CERDEC are part of the U.S. Army Research, Development and Engineering Command, which has the mission to develop technology and engineering solutions for America’s Soldiers.

RDECOM is a major subordinate command of the U.S. Army Materiel Command (AMC). AMC is the Army’s premier provider of materiel readiness — technology, acquisition support, materiel development, logistics power projection, and sustainment — to the total force, across the spectrum of joint military operations. If a Soldier shoots it, drives it, flies it, wears it, eats it or communicates with it, AMC delivers it.